| Prod Model: |

Metal Pole Clamp Bracket For Electric Power Pole |

| Product Name: |

Metal Pole Clamp Bracket for Electric Power Pole |

| Surface Treatment: |

Galvanization |

| Warrenty: |

15 Years |

| Lift Time: |

50 Years |

| Shape: |

Conoid, Multi-Pyramidal, Columniform, Polygon |

| Certificate: |

ISO, SGS, BV |

| Welding Standard: |

Aws D 1.1 |

| Tolerance: |

+/- 2% |

| Material: |

Q345, Gr65, Q235 as Per Customer Request |

| Usage: |

Angle Tower |

| Conductor Circuit: |

Single Circuit |

| Certification: |

CE |

| Materials: |

Steel |

| Standard: |

Standard |

| Style: |

Cable Tower |

| Structure: |

Metal Pole Clamp Bracket for Electric Power Pole |

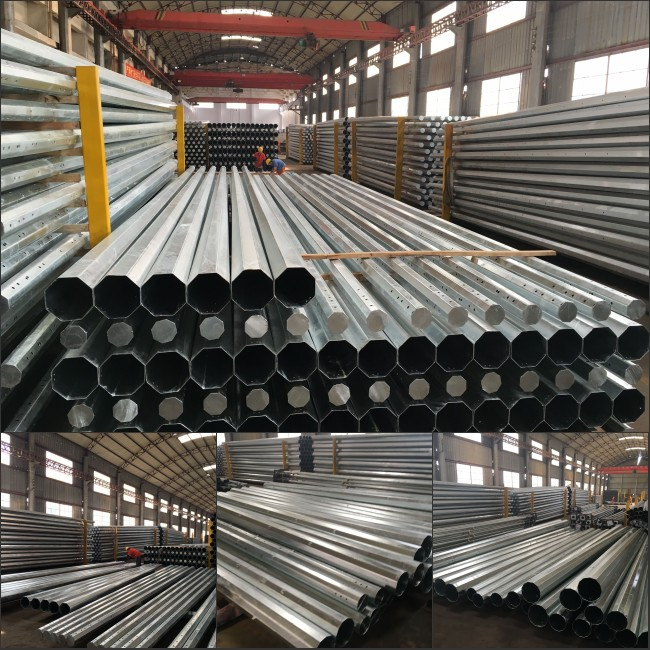

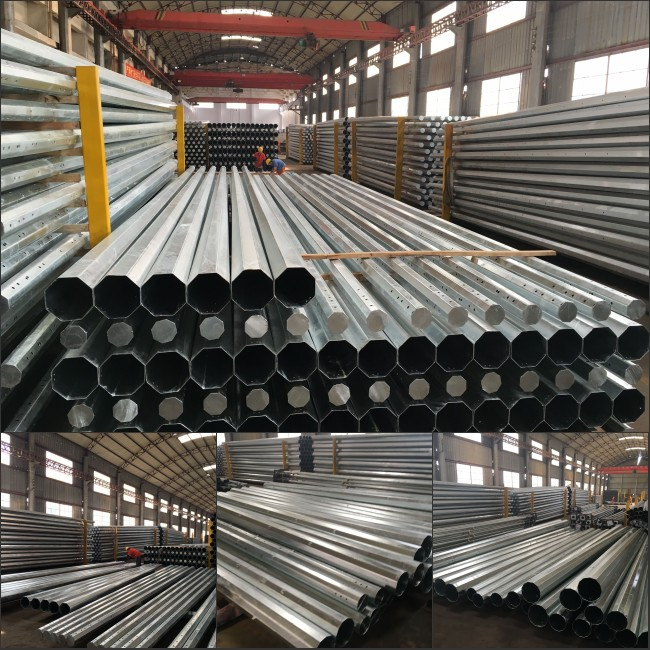

Product Description

Metal Pole Clamp Bracket For Electric Power Pole

Specification

| Type | Metal Pole Clamp Bracket For Electric Power Pole |

| Suit for | Electricity distribution

|

| Shape | Conoid ,Multi-pyramidal,Columniform,polygonal or conical

|

| Material | Usually Q345B/A572,minimum yield strength>=345n/mm2

Q235B/A36,minimum yield strength>=235n/mm2

As well as Hot rolled coil from Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, to ST52- |

| Torlance of dimenstion | +- 2% |

| Power | 10 KV ~550 KV |

| Safety Factor | Safety factor for conducting wine : 8

Safety factor for grounding wine : 8 |

| Design Load in Kg | 300~ 1000 Kg appliced to 50cm from the to pole |

| Marks | Nane palte through rivert or glue ,engrave ,emboss as per customer requirement |

| Surface treatment | Hot dip galvanized Following ASTM A 123, color polyester power or any other standard by

client required.

|

| Joint of Poles | Insert mode,innerflange mode,face to face joint mode .

|

| Design of pole | Against earthquake of 8 grade |

| Wind Speed | 160 Km/Hour . 30 m /s |

| Minimum yield strength | 355 mpa |

| Minimum ultimate tensile strength | 490 mpa |

| Max ultimate tensile strength | 620 mpa |

| Standard | ISO 9001 |

| Length of per section | Within 14m once forming without slip joint |

| Welding | We has past flaw testing.Internal and external double welding makes the welding beautiful

in shape

Welding Standard :AWS ( American Welding Society ) D 1.1

|

| Thickness | 1 mm to 30 mm |

| Production Process | Rew material test → Cutting →Molding or bending →Welidng (longitudinal )→Dimension verify

→Flange welding →Hole drilling →Calibration → Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Packages |

| Packages | Our poles as normal cover by Mat or straw bale at the top and bottom ,anyway also can following

by client required , each 40HC or OT can loading how many pcs will calculation base on the client

actually specification and data. |

Packing and Shipping

Our poles as normal cover by Mat or straw bale at the top and bottom and wood between the poles to avoide the damage on the galvanization of the pole ,anyway also can following by client required , The loading capacity of 40HC or OT an be calulated calculation base on the client actually specification and data.

Product Description

As an BV ,ISO ,SGS approved supplier in China ,we have more than 20 years produce and export steel pole ,and we can assure the pole we offered is of sound quality which made from qualified material with our professional workers and advance equipment.

Raw Material

When purchasing the raw material (steel plate), on sheet of mill certificate from mill factory must be enclosed. When the raw material arrives at the warehouse, the quality department must take the elongation test and the chemical composition analysis to make sure the raw material have meet all the standard that the needed before production.

Plasma Cutting

Cuting the raw material that have meet all the standard required into different length and width. CNC laser cutting is used to direct the material or the laser beam generated. A typical commercial laser for cutting materials would involve a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Molding

Forming the cutted steel plate into the shape (circular or polygonal or other shape ) that as per specified in the drawing. This invention relates to forming devices and more particularly to devices or machines for bending longitudinally rolled sections or strips of metal stock to desired curvilinear shapes.

Welding

After molding, weld the steel plate together. Usually it is longitudinal welds. It adopts A.C.inverter control, with functions of stable running and fast traveling speed; The seam-tracking arc-guide mechanism is three-spindle system to guarantee the alignment without aberrancy; The main frame and welding machine are intergrated control, with flux auto-recovering system and it is easy to operate with high efficiency.

Main Features

1. Price Term: EXW, FOB, CFR or CIF.

The price includes pole shaft, base plate, cross arm and anchor part.

Shipping seaport: Shanghai Seaport. For FOB, CFR or CIF price, please specify which exact model you need, and tell us your order quantity so that we can calculate the local transport charges and sea freight.

2. MOQ: 1 set for Customized

3. Payment: Typically 30% by T/T as deposit, balance by T/T or L/C at sight before shipment. Other payment way can be negotiated.

4. Delivery time : goods can be ready for shipment within 10 workdays after receiving deposit.

5. Warranty : 30 years

6.Surface treatment :hot dip galvanization

Our company

Established in 1991,Jiangsu Milky Way Steel Poles is located in Wuxi,East of China ,near one of the largest sea port of China ,Shanghai,Port .

Our Products have been widely used in the power transmsion ,signal transmission and ligting for street ,road ,square ,palaestra.and so on.

We have plenty of export experience . Since our first overseas order from Pakstan in 1991 of 132 KV transmission poels ,our products have been deliveried to more than 70 contries and areas ,including America,Australia ,Russia ,Genmery ,Span,Philippines ,Malaysia , Dominica, Congo, Togo and Guniea so on.

Estbilsed in 1991, Jiangsu Milky Way Steel Poles is located in Wuxi, East of China, near one of the largest sea port of China, Shanghai, Port.

Our Products have been widely used in the power transmsion, signal transmission and ligting for street, road, square, palaestra. And so on.

We have plenty of export experience. Since our first overseas order from Pakstan in 1991 of 132 KV transmission poels, our products have been deliveried to more than 70 contries and areas, including America, Australia, Russia, Genmery, Span, Philippines, Malaysia and so on.

To assure our products qualified, we take steps as follows:

1. Management team: We have employ the foreign export to take chaege of the overall managemnt, especailly the technical managemnt and quality management.

2. Introducing ISO management, We are awared ISO 9001: 2008 certificate...

3. Lofting and design software: We have transmisson power pole design software which can help us design all kinds of steel pole, at the same time, the TMA and LMA are adopted by us to provide the design the drawing accuratly.

4. QC Inpection: It is our company policy that all the finish product should be inspected by our specialzed QC in every manufacure steps and beofore every shipment.

We are always persisting in horzontal cooperation with domestic senior project institute and technical colleges. The enterprise also has an highly qualified team working at R&D, manufacure, QC, aftersales service and other important positions.