The Hydraulic cylinder Featuers:

1. Big lifting force:

Adopt high strength imported(Italy Marcegaglia ) materials, work under pressure up to 22 MPa, the unit weight of the lifting force is 10% ~ 20% higher than the similar products.

2. High security:

excellent structural design ensure the oil cylinder lift smoothly, improve safety operation and create the most valuable security guarantee for the user;

3. Stronger weather resistance:

The application new materials and special structures can adapt to different environment from cold to hot and can round-clock operation.

4. Best performance:

excellent performance product and longer lifetime brings visible benefit and no worries General model as below:

- Complete CNC Machining capabilities

- Bore size from 40mm to 800mm,

- Stroke lengths to 12000mm or longer

- Working pressures to 42Mpa

- Customized your needed hydraulic cylinder

1.product description | HS Code | 8412210000 |

| Application | Dump truck, Tipper, Trailer. |

| Material of cylinder tube | alloy steel |

| Seal | Hallite,SKF,NOK,Guarnitec,Parker |

| Coating | chrome plated |

| Temperature | -30ºC~100ºC |

| Hydraulic pressure | 16MP, 18MP or 22MP for your selection |

| Stroke | 630mm, 735mmm,750mm,900mm or per your requirements |

| Color | red black blue gray,can custom according request |

| Mounting Type | Earring-trunnion, double trunnion, double earring (eye end) |

| Plunger | 20#, 45# steel with high frequency quenching |

| Certification | ISO9001-2009 ,TS16949 |

| Package | shrink film, pallet, plywood case and carton |

| Warranty | One year after shipping arrival |

| Payment terms | T/T, L/C, West Union,Paypal |

| Delivery time | 15- 30 days after down payment |

| Model | Bore Diameter (mm) | Rod Diameter (mm) | Stroke (mm) | Installation distance (mm)

| Pressure (MPa) | Rated thrust (ton)

| Lift (ton) | Capacity (L) |

| HG-E180x560ST | 180 | 80 | 560 | 1000 | 16 | 40.7 | 15~25 | 11.4 |

| HG-E180x660HX | 180 | 80 | 660 | 1050 | 16 | 40.7 | 15~25 | 13.48 |

| HG-E180x680ST | 180 | 80 | 680 | 1140 | 16 | 40.7 | 15~25 | 13.89 |

| HG-E180x720SY | 180 | 80 | 720 | 1125 | 16 | 40.7 | 15~25 | 14.7 |

| HG-E180x760HJ | 180 | 80 | 760 | 1170 | 16 | 40.7 | 15~25 | 15.52 |

| HG-E180x780ST | 180 | 80 | 780 | 1140 | 16 | 40.7 | 15~25 | 15.93 |

| HG-E180x790SX | 180 | 80 | 790 | 1130 | 16 | 40.7 | 15~25 | 16.13 |

| Model | Bore Diameter (mm) | Rod Diameter (mm) | Stroke (mm) | Installation distance (mm) | Pressure (MPa) | Rated thrust (ton) | Lift (ton) | Capacity (L) |

| HG-E160x490ST | 160 | 70 | 490 | 860 | 16 | 32.1 | 10~20 | 7.97 |

| HG-E160x560ST | 160 | 70 | 560 | 1000 | 16 | 32.1 | 10~20 | 9.10 |

| HG-E160x650SX | 160 | 70 | 650 | 1000 | 16 | 32.1 | 10~20 | 10.57 |

| HG-E160x680ST | 160 | 70 | 680 | 1140 | 16 | 32.1 | 10~20 | 11.06 |

| HG-E160x700BH | 160 | 70 | 700 | 1025 | 16 | 32.1 | 10~20 | 11.38 |

| HG-E160x720ZY | 160 | 70 | 720 | 1125 | 16 | 32.1 | 10~20 | 11.71 |

| HG-E160x780ST | 160 | 70 | 780 | 1145 | 16 | 32.1 | 10~20 | 12.68 |

| HG-E160x790SX | 160 | 70 | 790 | 1155 | 16 | 32.1 | 10~20 | 11.71 |

| HG-E160x800BH | 160 | 70 | 800 | 1125 | 16 | 32.1 | 10~20 | 13.01 |

| Model | Bore Diameter (mm) | Rod Diameter (mm) | Stroke (mm) | Installation distance (mm) | Pressure (MPa) | Rated thrust (ton) | Lift (ton) | Capacity (L) |

| HG-E220x760XM | 220 | 100 | 760 | 1080 | 16 | 60.8 | 20~35 | 22.92 |

| HG-E220x780HW | 220 | 100 | 780 | 1220 | 16 | 60.8 | 20~35 | 23.52 |

| HG-E220x900HJ | 220 | 100 | 900 | 1190 | 16 | 60.8 | 20~35 | 27.14 |

| HG-E220x910XM | 220 | 100 | 910 | 1210 | 16 | 60.8 | 20~35 | 27.45 |

| HG-E220x920HW | 220 | 100 | 920 | 1200 | 16 | 60.8 | 20~35 | 27.75 |

| HG-E220x1034ZY | 220 | 100 | 1034 | 1370 | 16 | 60.8 | 20~35 | 31.18 |

| Model | Bore Diameter (mm) | Rod Diameter (mm) | Stroke (mm) | Installation distance (mm) | Pressure (MPa) | Rated thrust (ton) | Lift (ton) | Capacity (L) |

| HG-E200x720SY | 200 | 100 | 720 | 1125 | 16 | 50.2 | 15~30 | 16.96 |

| HG-E200x750SS | 200 | 85 | 750 | 1165 | 16 | 50.2 | 15~30 | 19.31 |

| HG-E200x770HW | 200 | 100 | 770 | 1120 | 16 | 50.2 | 15~30 | 18.14 |

| HG-E200x780ST | 200 | 100 | 780 | 1145 | 16 | 50.2 | 15~30 | 18.38 |

| HG-E200x850ST | 200 | 100 | 850 | 1230 | 16 | 50.2 | 15~30 | 20.03 |

| HG-E200x900HJB | 200 | 100 | 900 | 1190 | 16 | 50.2 | 15~30 | 21.21 |

| HG-E200x910LN | 200 | 100 | 910 | 1210 | 16 | 50.2 | 15~30 | 21.44 |

2.Certification

3.Cylinder Advantages:

- Main export market:USA, Canada, South Korea, Russia, Australia, Indonesia, Malaysia, Fiji Island, Kenya, Philippines, Bolivia, the United Arab Unites,Singapore

- Material:Alloy steel,Carbon steel,Stainless steel,27SiMn

- Seal:Kaden,Hallite, Parker,NOK,SKF etc

- Rod :Chrome plated and quenched.Has good mechanical properties, long service life

- Cylinder:Honing machining /boring /rolling

- Hydraulic Cylinders Certification ISO9001:2009, SGS, TS16949, RoHS, CNAS Certification

- Experience in export North America, Australia, Asia, Middle East, Africa

- We are professional manufacturer and supplier in hydraulic cylinder.

- We do accept OEM manufacturing. We will provide competitive price and make the exact cylinder according to your specification and drawing.

- We have professional R&D team with rich design experience.

- We also establish strict but scientific product testing system so that products have perfect performance.

- One year warranty and long time track service is offered to solve any problems you meet after sale.

4.Quality control

- All specification is designed by professional engineer

- All material is high quality-Seal kits are purchased from USA, Japan, UK and Sweden.

- All material is processed by skilled workers and advanced CNC lathe

- All cylinders are 100% tested before package to ensure every cylinder is qualified for its purpose

- Package is air cushion film for each cylinder and steel case for all cylinders to ensure goods can arrive at customer safely

We firmly believe that quality products from the outstanding design and concept,engineers with rich experience in our strong technical team. Analyzes, calculations, strength check and motion simulation in variety of software to make our design more close to actual working conditions, We will consider various factors in the design stage to avoid each risk of project failure. Our design and products could perfectly match customers' varied needs.

5.Product Process:

1. Raw materials entering the factory, 27SiMn, 40CrMo, ST52, 45# steel tubes or bars for choice

2. Do the pre-treatment including pickling, phosphating and saponification, and then cold-draw the seamless steel tubes.

3. Put the steel tubes into the tempering furnace to do the stress relief annealing in convenience of the subsequent the processing.

4. Multi-roll straightening machine, with 10 straightening points, achieves the automatic rolling straight improving the efficiency greatly

5. Heat treatment to obtain work pieces with different properties by changing their internal microstructure or surface chemical composition.

6. Cylindrical degree can be controlled within 0.03mm and the surface roughness is up to 0.4 by honing with range:φ40mm-φ450mm and longest length: 12000mm

7. Machining processes to obtain high precision parts with complex shapes strictly according to the detailed drawings.

8. Electroplating production process fulfills the functional and ornamental requirements for coating work pieces of different dimensions according to specific application requirements.

9. Cleaning all the parts by automatic cleaning machine in the special solution and under special temperature control effectively.

10. All the parts are assembled into complete cylinders according to the strict assembly instructions by skillful workers in dust-free workshop.

11. Do proof pressure and performance tests to check whether the cylinders can operate smoothly and stably under the specified pressure with no leakage and deformation.

12. Do the painting including high quality primer and topcoat to obtain beautiful appearance and protect the cylinders against the anticorrosion.

13. Wooden pallet or boxes packing with plastic films wrapped on the surface, suitable for long-time sea transport.

6.How do we ensure product quality?

piston rod:

1: hard chrome plating

2: thickness of 0.03-0.05mm;

3: in-house salt spray test

cylinder tube:

1: standard material-#45, SAE1045, CK45

2. surface roughness: Ra0.4-0.08micron

Seals:NOK, Hallite, Parker etc.

Welding:mannual & machine welding

Professional manufacturer& supplier of Hydraulic Cylinders

Hydraulic Cylinders Certification ISO9001:2009, SGS, TS16949, RoHS, CNAS Certification

Experience in export North America, Australia, Asia, Middle East, Africa

Hydraulic Cylinders can be Make according to client's requirements

One year warranty and long time track service is offered to solve any problems you meet after sale.

7.FAQ:

1.are you a manufacturer?

Yes, we focus on the hydraulic cylinder.

We are professional manufacturer in hydraulic cylinder. We will provide competitive price.

2. Can I get samples to test before starting cooperation?

Of course.We would like produce sample hydraulic cylinder for your confirmation.

3. Have you been exported to overseas?

We have been exporting to USA, Canada, Germany, Italy, France, Russia, etc.

4.How to ship your product?

We are transported by sea, by air or by international express.According to your needs.

5. Do you support OEM service?

Yes. OEM service is available.

we can make products according to your requirements. Please kindly send us your specifications and drawings.

6. Is your design reasonable?

We have professional R&D team with rich design experience.

We also establish strict but scientific product testing system so that products have perfect performance.

7. How to choose which model hydraulic cylinder to buy?

Please kindly send us your drawings, models or providing us your parameters and

specification of the hydraulic cylinder like sleeves O.D., total stroke, rated pressure, closed length, vehicle body length, etc. We can determine the most suitable model for you.

8. What is your warranty?

Our products are all available for one year free warranty and product lifetime consulting service.

9. How long it will take from ordering to delivering?

It depends on the ordering quantity. Generally, we will take 15-30days. If there are any changes, we will inform you in time.

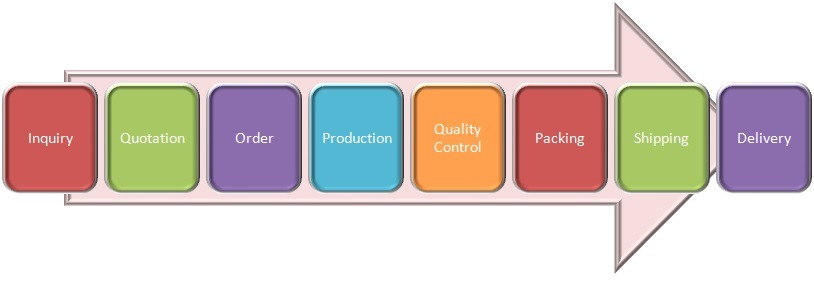

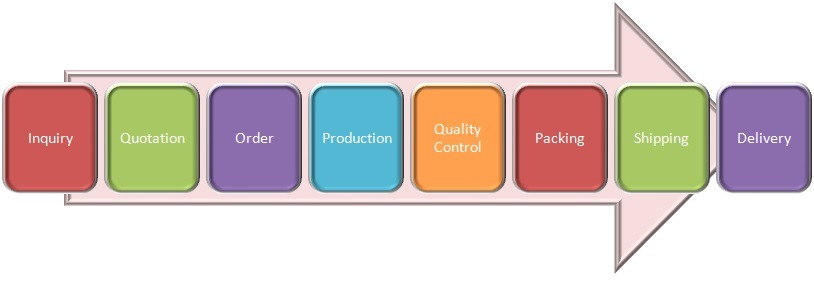

8.Purchasing process