Home Toolbuy Products Stainless Steel Precision Casting Steel 304 Lost Wax Casting for Machinery Parts

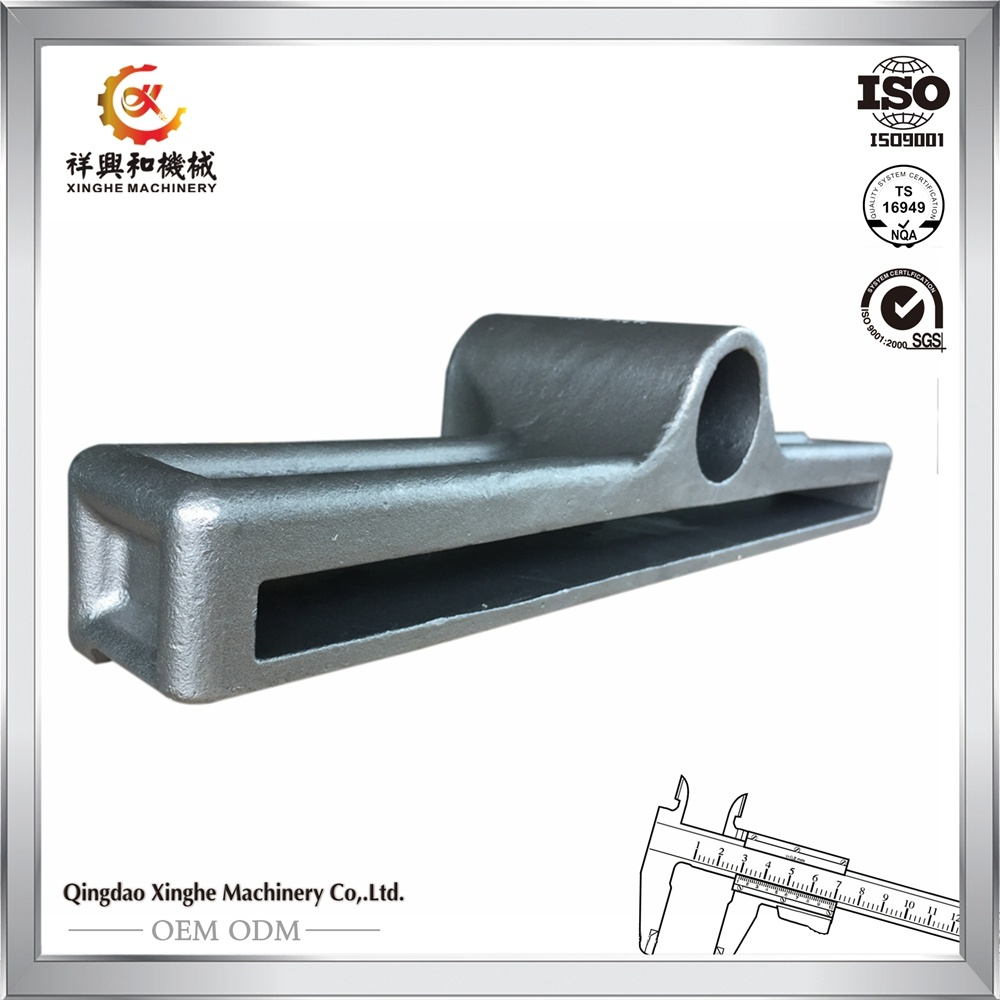

Stainless Steel Precision Casting Steel 304 Lost Wax Casting for Machinery Parts

| Price: |

US $ 3800-5860/Ton |

| Min Order: |

10/Ton |

| Pay Type: |

L/C,T/T,D/P,Western Union,Paypal |

Stainless Steel Precision Casting Steel 304 Lost Wax Casting for Machinery Parts

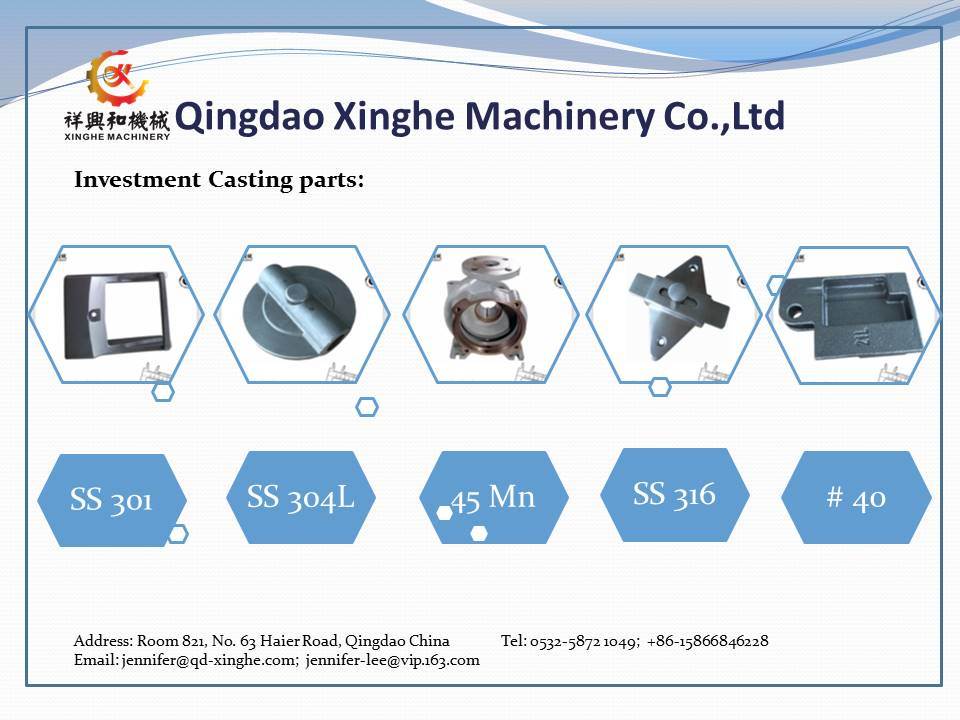

Qingdao Xinghe Machinery Co.,Ltd

Custom Metal/Water Glass/Steel/Iron/Aluminum Casting

Product details: 1.OEM and ODM

2.Technology: sand casting, investment casting, precision

3. Material: brass, steel, iron, aluminum

4. Product weight: From 0.5~100kg;

5. Machining equipment: CNC, Lathe machine, Milling machine, Drilling machine, and so on;

6. Test equipment: Optical Spectrum Analyzer, CMM, Hardness test equipment, Tensile test machine;

7. Surface treatment: Powder coating, Painting, Sand blasting.| Process | investment casting, precision casting, lost wax casting, silica sol process, soluble glass process |

| Processing ability | Surface finishment: Ra1.6-Ra3.2 |

| Size tolerance: VDG P690 D2 |

| Maximum size: ≤1200mm×800mm×400mm |

| Weight range: 0.1Kg-120Kg |

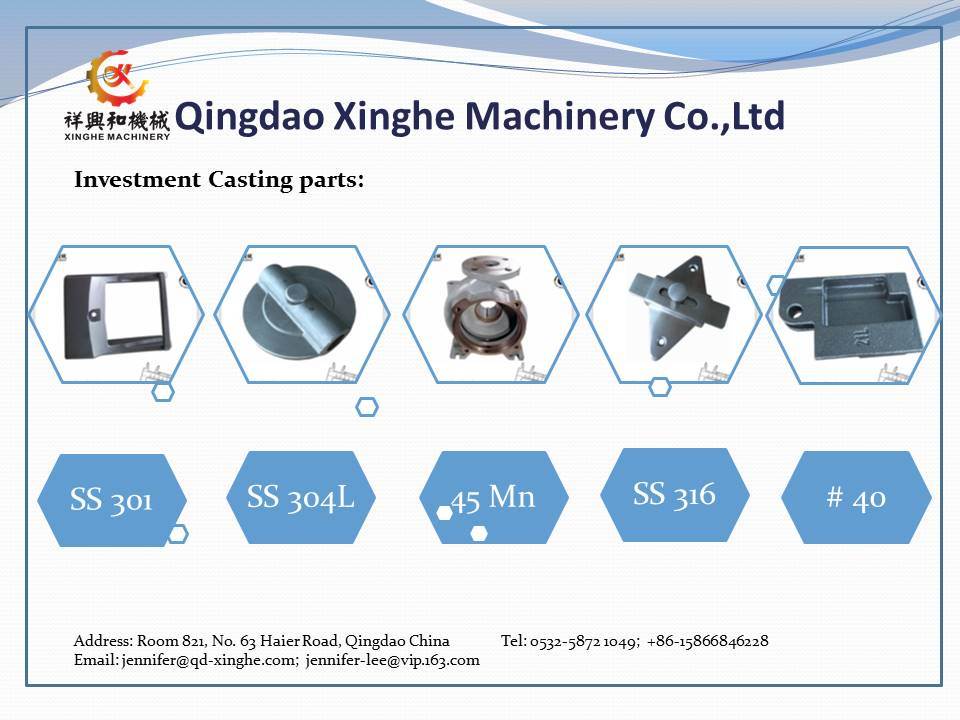

| Material | stainless steel, carbon steel, alloy steel,heat-resistant steel, tool steel |

Brass CuZn38,H62

Aluminum bronze AB2,863 |

| Cast aluminium alloy ZL101,ZL114A,A356 |

| Application | Mechanical Components

Boat parts and Marine hardware

Construction hardware

Auto parts and accessories

Medical Instrument parts

pump & valve parts and accessories

Impellers and propellers(propellers)

Pipe Fittings or pipeline accessories

Other industry metal casting parts |

| DESIGN | Various type of 2D or 3D drawings are acceptable,such as JPG,PDF,DWG,DXF,IGS,STP,X_T,SLDPRT etc. |

| STANDARDS | AISI,ATSM,UNI,BS,DIN,JIS,GB etc. |

| INSPECTION | Dimension inspection

Chemical composition analysis (Spectrum analysis)

Mechanical property testing

X-Ray inspection

Dye Penetrant Inspection

Magnetic powder inspection

Metallographic inspections |

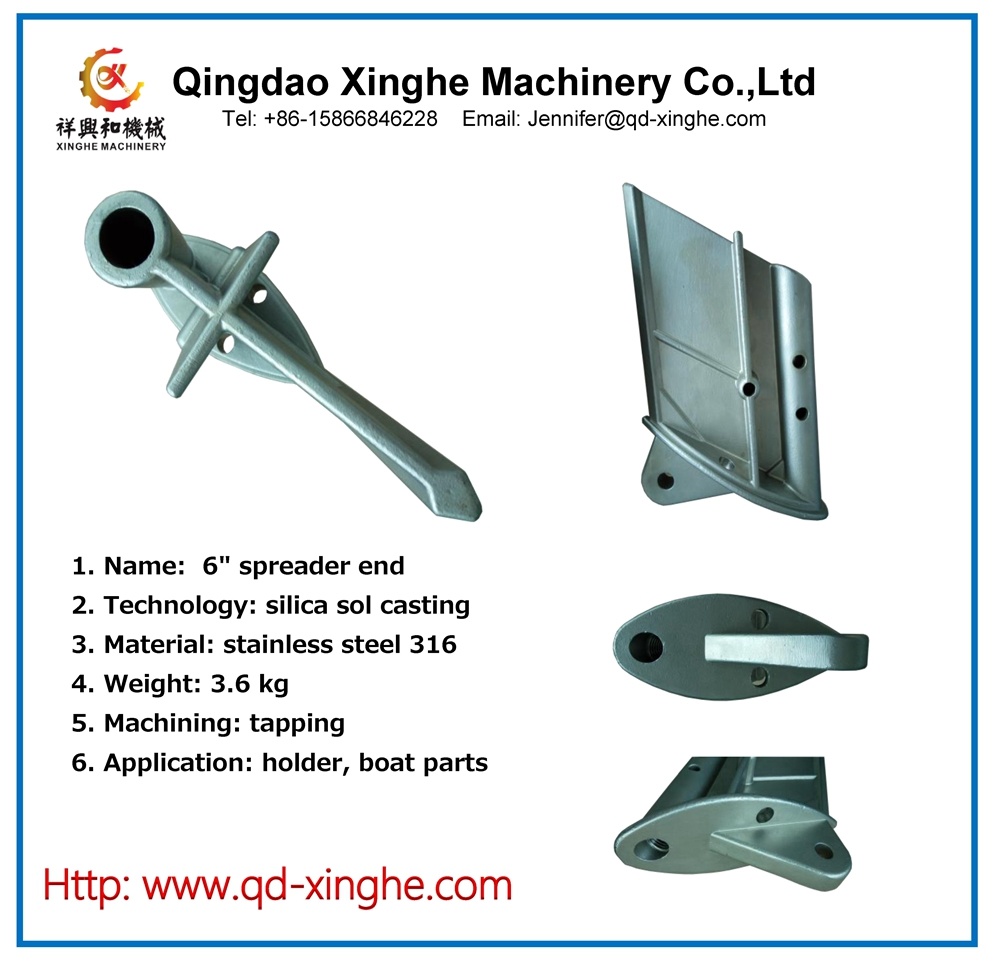

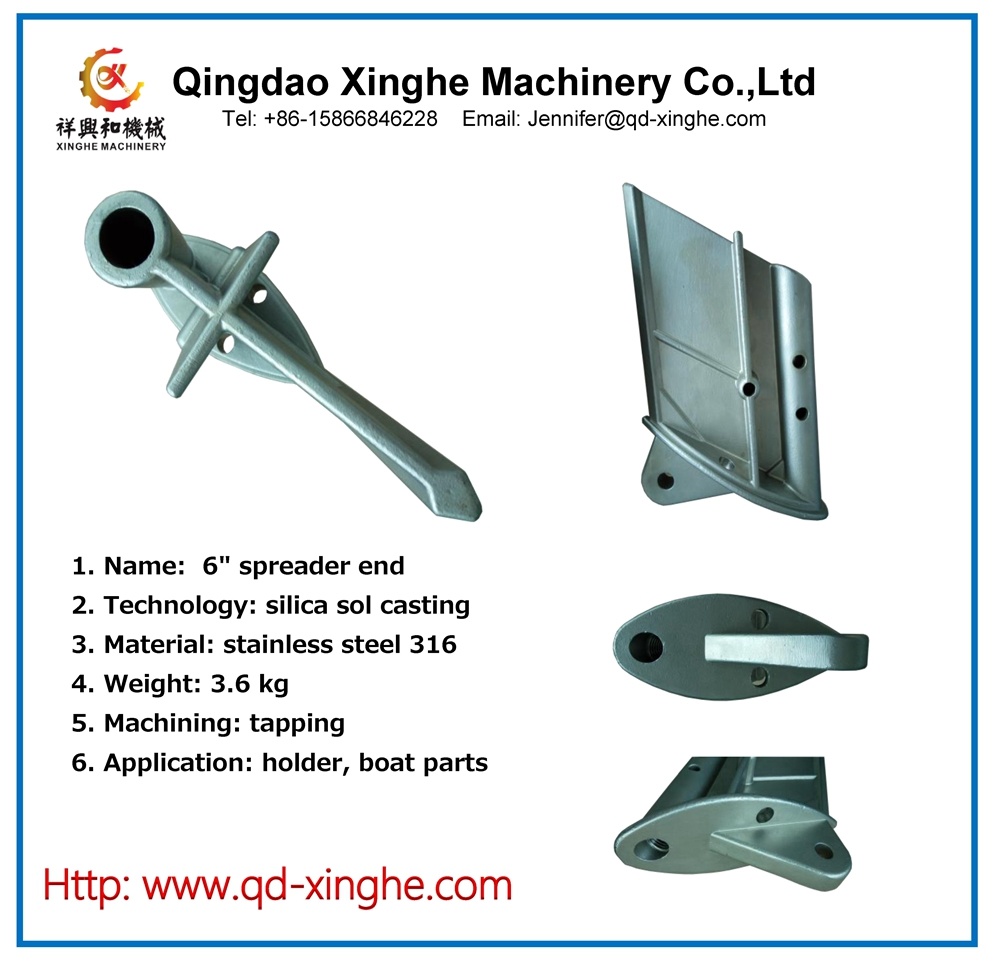

| Process | Investment/Lost wax casting(Silica sol/Waterglass process) |

| Specification | 1.Material: SS304/CF8,316/CF8M,316L,904L,etc.

2.Standard: ASTM\DIN\BS\JIS\GB.

3.Surface finish: shot blasting, sand blasting, polishing, or as your requirements.

4.Weight:0.1-100kg.

|

| Production Facility | 1.Casting facility: wax injector, medium-frequency induction furnace, box resistance furnace, heat treatment furnace, flame cutting machine, shot-blasting machine, sand-blasting machine.

2.Machining facility: CNC,NC lathe,ordinary machine tools,NC milling machine, polishing machine. |

| Heat Treatment | Solution treatment. |

| Test and Inspection | Chemical composition, mechanical property, hardness test, impact test, PT, etc. |

Contact us today!

Frank

T: 008615588626145

| Prod Model: |

OEM |

| Item: |

Metal Casting |

| Technology: |

Precision Casting |

| Secondary Machining: |

Drilling, Tapping, Milling, Grinding Cast Iron |

| Surface Finish: |

Polishing, Anodising, Powder Coating etc |

| Tolerance: |

+-0.5mm or Ad Request |

| Weight Range: |

0.1-1000kg |

| Name: |

Metal/Water Glass/Silica Sol/Steel Casting with Al |

| Delivery Time: |

25-30 Days |

| Brand Name: |

Xh |

| Products: |

Casting Parts |

| Casting Form Material: |

Metal |

| Casting Metal: |

Cast Steel |

| Casting Form Usage Count: |

Semi-permanent |

| Casting Method: |

Precision Casting |

Qingdao Xinghe Machinery Co., Ltd. Jointly manufactures and exports a variety of casting products for architectural, automotive, mechanical parts. We export to more than 20 countries on 6 continents and have been doing so for more than 10 years.

Our main product line includes sand casting, precision casting, die casting, forging, stamping, welding and CNC machining. Materials vary from grey iron, ductile iron, bronze, aluminum, steel, stainless steel, and so on.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

Moreover, in order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1) Incoming material inspection

(2) Inspection of work-in-progress

(3) Finished product inspection

(4) Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today. We will sincerely create and share success with all clients.