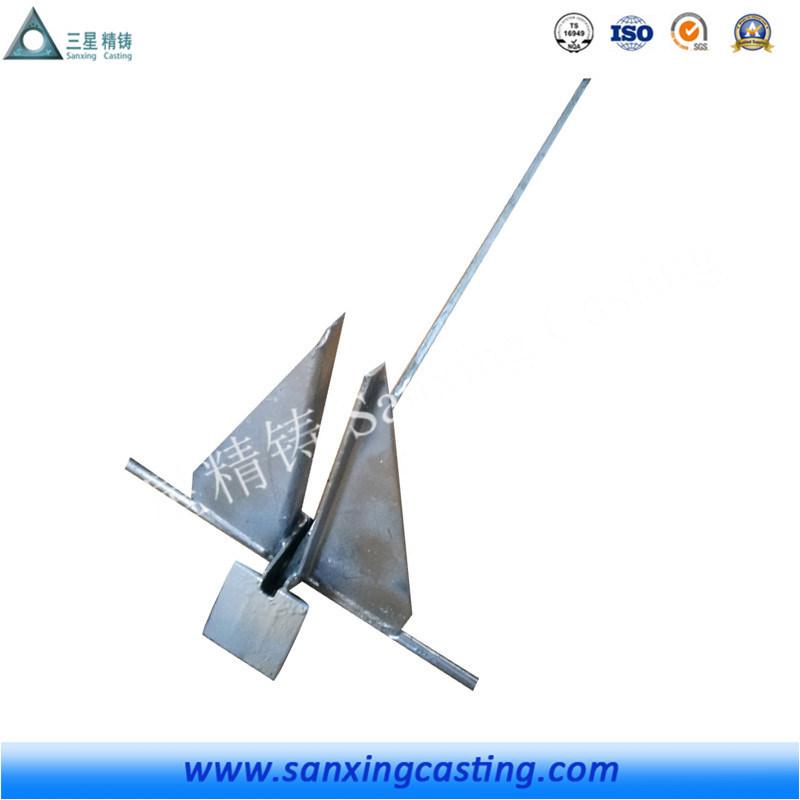

Stainless Steel Boat Anchor Marine Hardware

| Price: |

US $ 2000-5000/Ton |

| Min Order: |

1/Ton |

| Pay Type: |

L/C,T/T |

Product Description

We are professional manufacturer of marine hardware, anchors, cleats and so on.1) Type: Bruce type anchor, Swivel plow anchor, Plough anchor, Folding Anchor and Danforce anchor2) Competitive price and nice quality3) Material: Stainless steel 316 or carbon steel, carbon steel4) Surface finish: Mirror and hot dipped galvanized5) Standard: Metric and UNF6) Customer design: Our experienced engineer team can developed the products and manufacture in accordance with samples, drawings or only ideas7) Delivery: By sea, by air or by express service8) Price term: FOB or CIF9) Size: From 0.5kg to 80kg10) Packaging: Clean plastic bags and cartons and pallets or as per request11) For more marine hardware, please email us for full catalogues

Production Ability: 760 employees, 20 R&D engineers, 25 QC staffs, 3 production lines, different production machines, such as CNC lathe machines, Shot blasting machine, Polishing machines, Sand blasting machines, Milling machines etc. Our annual output up to 30000 tons.

Production Standard: AISI, ASTM, DIN, GB, BS, JIS, NF, AAR, ISO9001, SGS, CE etc.

Investment Casting Detailed Information| Material | stainless steel ,carbon steel ,alloy steel, brass, aluminum,zinc alloy,

ductile Iron,,grey iron, etc,according to customer drawings and specifications. |

| Casting process | Silica Sol casting , Lost Wax casting, composite casting,

soluble glass casting, sand casting, gravity casting etc. |

| Additional machining | turning , milling, drilling, grinding, threading, CNC machining, etc. |

| Surface treatment | sand blasting, polishing, plating, acid treatment, anodizing, painting, powder coating,passivating,electropolishing ect. |

| Tolerance | profile dimension +/-0.02mm, hole diameter +/-0.005mm. |

| Report available | Material chemical compsition report, Mechanical Property report and dimenal report |

| Drawing software | PRO/E, Auto CAD, Slid Work, UG, etc |

| Lead time | 30-45 days |

| Package | individual pack by bubble bag inside the carton, no more than 35lbs

per caton,pallet or wooden case is outside packaging. |

| Application | Industrial machinery parts, Marine hardwares, Pipe Fitting Parts,

Textile machinery parts, Sport facility parts, Pneumatic tools parts,

Fluid equipment parts, Copper alloy parts, Food machinery parts,

Auto parts, Elevator Parts, Air compressor Parts,

Electric machine & hardware fittings, Mining & earthmoving

machinery accessories, pump body and valve

|

Our Advantages1) We can do the casting,forging and accembly by our own factory 2) Strict qualitify control for the raw material 3) Perfect production process for each part4) The most advanced equipments for production and inspection5) On time delivery 6) Flexible payment way7) FCL or LCL both acceptable8) Diversified packaging according to requirement

Our Advantages1) We can do the casting,forging and accembly by our own factory 2) Strict qualitify control for the raw material 3) Perfect production process for each part4) The most advanced equipments for production and inspection5) On time delivery 6) Flexible payment way7) FCL or LCL both acceptable8) Diversified packaging according to requirement Our Inspection EquipmentDirect-reading spectrograph, metal lographic microscope,hardness tester,brinell hardness tester,thermometric indicator,universal testing machine,carbon and silicon analysis meter,magnetic powder flaw detector,digital ultrasonic flaw detector etc.Our Service:1.Your inquiry related to our products or prices will be replied in 12 hours.2.Individual formula according to customers' special drawing requests.3.Manufacturer with large capacity,ensures the fast production cycle afterconfirming the order.4.Protection of sales area and private information for all of our customers.

Our Inspection EquipmentDirect-reading spectrograph, metal lographic microscope,hardness tester,brinell hardness tester,thermometric indicator,universal testing machine,carbon and silicon analysis meter,magnetic powder flaw detector,digital ultrasonic flaw detector etc.Our Service:1.Your inquiry related to our products or prices will be replied in 12 hours.2.Individual formula according to customers' special drawing requests.3.Manufacturer with large capacity,ensures the fast production cycle afterconfirming the order.4.Protection of sales area and private information for all of our customers.

Solutions

OEM / ODM

If you ...

1. Are looking for OEM/ODM manufacturers in this industry.

2. Need someone that can produce what you want and have a custom design printed to your specification.

Then our OEM/ODM service is for you!

Sample Order

If you…

1. Want to purchase a sample order first.

2. Purchase a full order after validating the product quality.

Then our Sample Order service is for you!

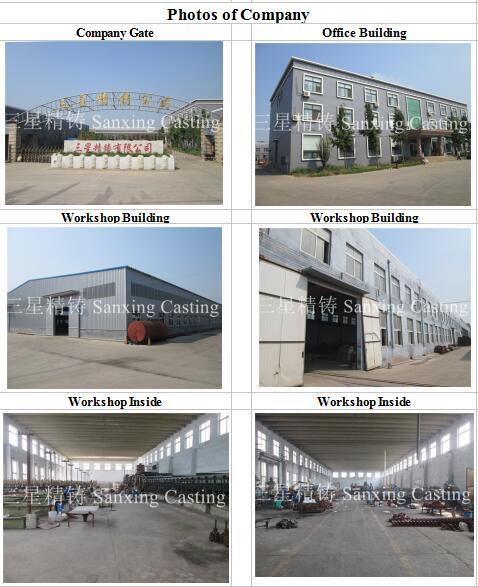

Factory Tour

If you...

1. Would like more information about our company.

2. Would like to visit China and are interested in working with us.

Then our Factory Tour service is for you!

If you have any question or need any help, please feel free to contact us.

Anna Qu

| Prod Model: |

SX091 |

| Usage: |

Ship Anchorage |

| Surface: |

Mirror or Hot DIP Galvanized |

| Machining: |

CNC Machine |

| Type: |

Inland and Coastal Boats |

About Us

Our company was established in 1996, it covers a total area of 10,000 square meters and now has about 760 employees, including 10 engineers and 60 technicians.The company owns two modern types of energy-saving & environmentally-friendly production lines including two fully automated wax and shell making process flow line, as well as two mesh belt furnace heat treatment production lines.It is fully equipped with complete and advanced CNC machining equipment.In addition to the casting, machining, it also has the facility to do hot galvanizing.Our company also has the most advanced and complete inspection equipment in the casting industry, including Spectrometer, Metallographic Microscope, Tension Tester, Low Temperature Tester, X-ray Tester, MPT, UT, CMM, Video Measurement Machine and so on.With these advanced facilities & instruments, we are able to supply the most precise finished products to our customers, and make products meeting their overall inspection requirements on chemical composition, mechanical properties, non-destructive testing and high precise dimensional inspections.

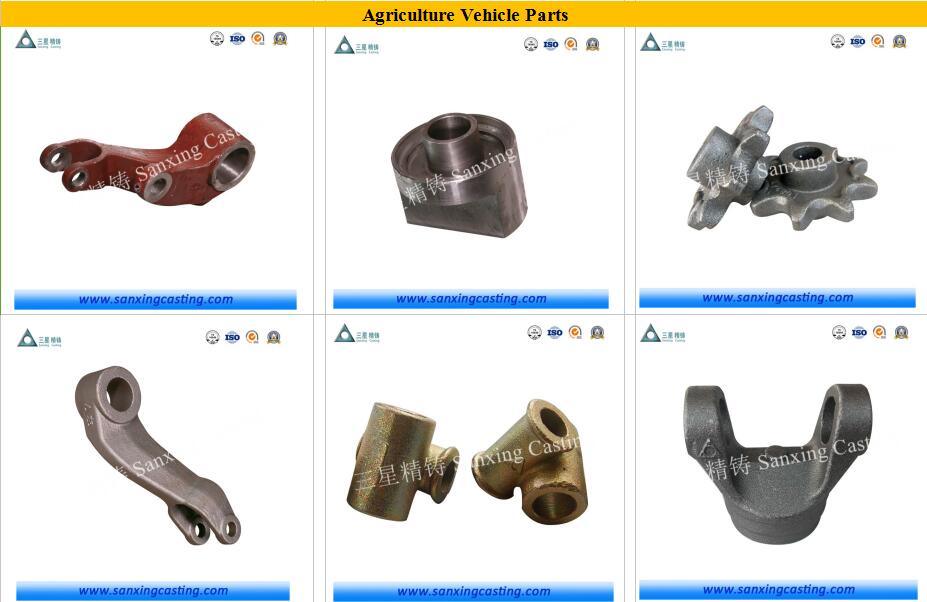

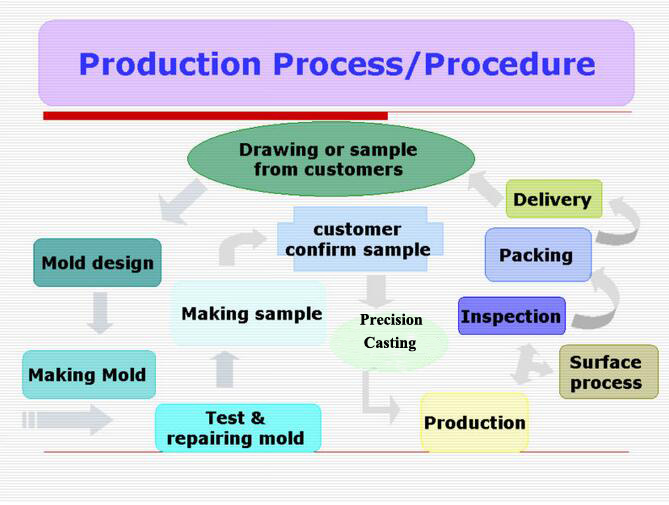

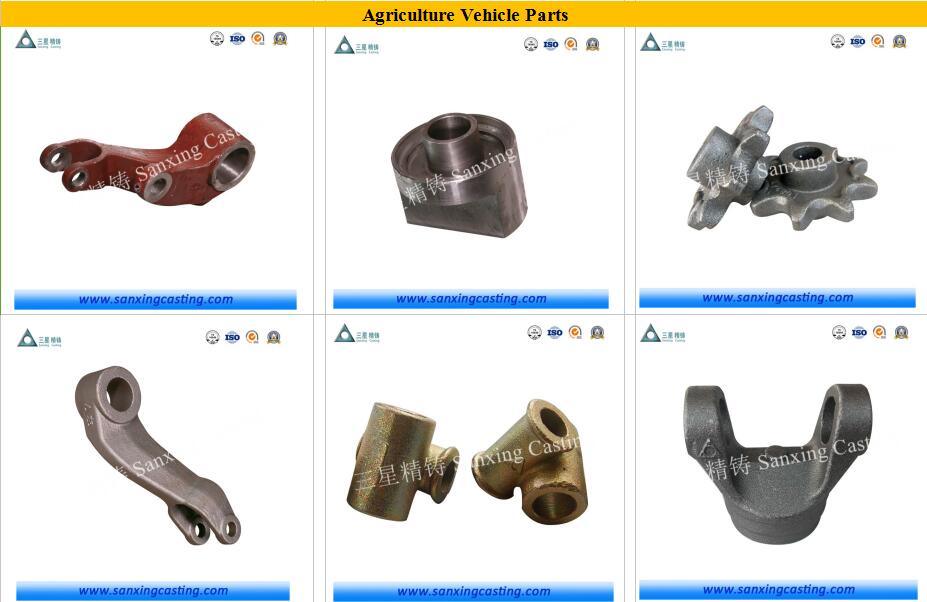

Our Production

We can offer you investment casting parts, railway casting parts, railway parts, excavator machinery parts, mining machinery parts, engineering machinery, agricultural machinery parts, sand casting, auto parts, stamping & forging, and valve parts.We are capability in manufacture non-standard metal machining.

1.Investment casting sand casting/ lost wax casting/precision casting/gravity casting/stainless steel casting/carbon steel casting etc.

2.Materials:Carbon steel, stainless steel, alloy steel etc;

3.Surface treatment:Polishing, zinc plating, chrome plating, Heat treatment, machining, nickel plating, electropolish, anodizing, hard anodizing, powder coating,galvanized and painting.

4.Software for specification drawings:PDF, auto CAD, solid work;

5.Main production equipments:Wax injection, CNC-machine, heat treatment;

6.Quality assurance in accordance with ISO9001:2008, strict material inspection and exact dimension control, 100% quality control.

7.OEM/ODM order is welcome;

8.The parts can be made completely based on your specifications such as drawing, design, sample etc.

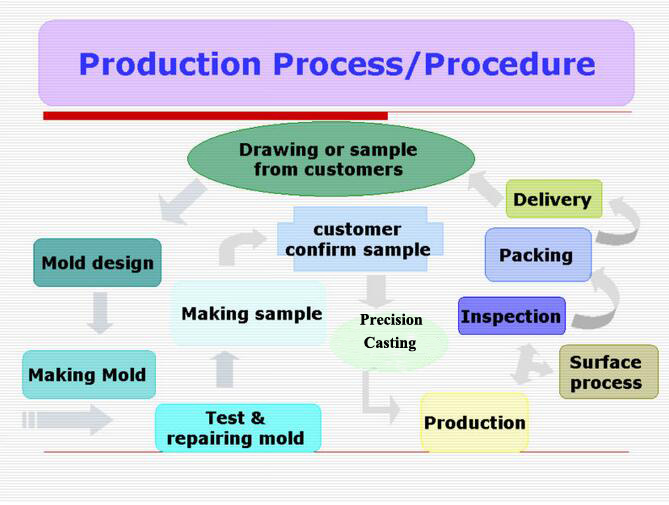

Production Process:Sanxing Precision Casting Co., Ltd can produce investment castings, lost wax castings, die castings, sand castings, CNC machining, precision casting, stainless steel casting, carbon steel casting.

Production Ability:760 employees, 20 R&D engineers, 25 QC staffs, 3 production lines, different production machines, such as CNC lathe machines, Polish machines, sand blasting machines, milling machines and so on, 10000 tons per year and 800 tons per month finish products.

Product Applied Field:Our products can be used in various areas:Machine parts, motor vehicle industry, mining industry, electrical industry, agricultural equipment, hydraulics industry, railway, marine engineering, public works, building industry.

Production Standard:AISI, ASTM, DIN, GB, BS, JIS, NF, AAR, ISO

Our Advantages

1.More than 20 years of experience in manufacturing and exporting

2.OEM and custom-made service

3.All kinds of castings and forgings can be manufactured according to drawing, sample or specific industry standard accurately.

4.Both parts and complete sets can be supplied

5.Strong engineering team makes high quality products

6.The coordinated service(Forging or Casting,Machining,Surface Heat Treatment) make lower price possible

7.Advanced-Level Equipments

8.Full material testing process and quality control system

9.18 months quality warranty and on time delievery

10.Small Order acceptable

11.Factory price

12.Offer customized packing

Our company would like to sincerely invite the global prospective buyers to pay a visit and have a good cooperation for a splendid future together.We will provide you not only the most satisfactory processing service but also very competitive price.