OEM/Standard Silicone Rubber Seal Sealing Gasket Aflas O Ring

| Price: |

US $ 0.1/Piece |

| Min Order: |

500/Piece |

| Pay Type: |

T/T,Western Union,Paypal |

Custom O Ring Rubber Seal Ring Oil Resistance Custom Aflas O-Ring /O Ring Suppliers With High Temperature Resistance

More than 500 sets different size O Ring tooling, good quality, quickly lead time. welcome OEM&ODM Order.

| Technical Specification | |

| Material | NBR, NR, EPDM, Viton,FVMQ,HNBR,LSR,CR,Silicon, PU,SBR,IIR |

| Size/Color | Customized |

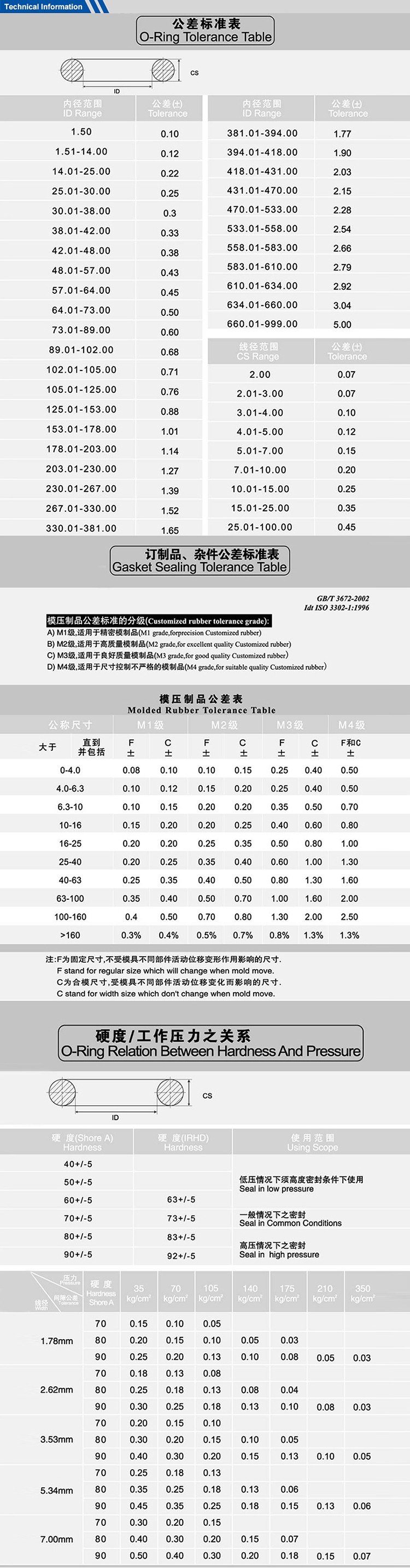

| Hardness | 20-90 Shore A |

| Processing Way | Compression, injection, injection transfer, extrusion, silicone liquid injection |

| Certificates | SGS, RoHS. Reach |

| Packing | PE plastic bags then to the carton / as customized |

| Payment | T/T, Paypal, Western Union,Payoneer |

| MOQ | 5000 PCS |

| Shipping Method | SEA,AIR,DHL,UPS,FEDEX,TNT, etc. |

| Delivery Time | 7 days for prototype tooling & samples, 14 days for production mold, 14-28 days for MOQ |

| Full Name of Material | Nitrile Rubber (Buna-N/NBR)

Natural Rubber(NR)

Ethylene-propylene (EPR, EPDM)

Fluorocarbon (FKM/FPM/VITON)

Fluorosilicone(FVMQ)

Hydrogenated Nitrile (HNBR)

Liquid Silicone Rubber(LSR)

Neoprene Rubber(CR)

Silicone Rubber

Polyurethane(PU)

Styrene-butadiene Rubber (SBR)

Butyl Rubber(IIR) |

| Prod Model: |

ML18135 |

| Color: |

Black/Red/ Customized |

| Hardness: |

30-90 Shore-a or Irhd |

| Certification: |

RoHS, Reach. FDA |

| Standard: |

Customized |

| Application: |

Pumps/Valve/Customized |

| Performance: |

Temperature/Wear/Customized |

| Shape: |

O-Ring/Customized |

| Type: |

Oil Seal/Dust Seal/Customized |

| Material: |

EPDM/NBR/Viton/Silicone/Ffkm |

Melon, established in 2007, is located in zhongshan city, guangdong province, China, our manufacturer workshop covers an area of 2000 square meters, staff 70 people, including 10 technical staff, 5 quality management staff, 6 sales staff, and over more 40% employee work in Melon more than 7 years, we love our manufacturer and provide an experienced, quality service from mould and tooling design, material selection through prototyping to production.

As a recognised experienced rubber factory enable us to advise our customer of the most suitable rubber or silicone or plastic moulding parts to be used for their application. Our engineer work closely with your design engineers and we help ensure your products meet specification. Our in-house specialists can advise on material selection, including: NR/SBR/EPDM/SIR/CR/SBR/IIR/HNBR/FKM/PU. Melon has continually implemented new technologies to meet the changing needs of our customers.

Not only can we manufacture your existing rubber or plastic parts, but we can also support new projects/products by assisting with design and prototyping. We also provide an in house tool making/tool-refurbishment service. Please contact us for more details.

Transfer Molding & Compression Moulding

Liquid Injection Molding (LSR)

CNC machining (Prototype Tooling)

Rubber&Silicone&Plastic mold

Proprietary bonding processes (with metal, plastic)

Research and development of new rubber formula

Trained professional production team and standardized quality control

Knowledgeable sales team and design engineers

One-stop manufacturer with competitive price