Product Description

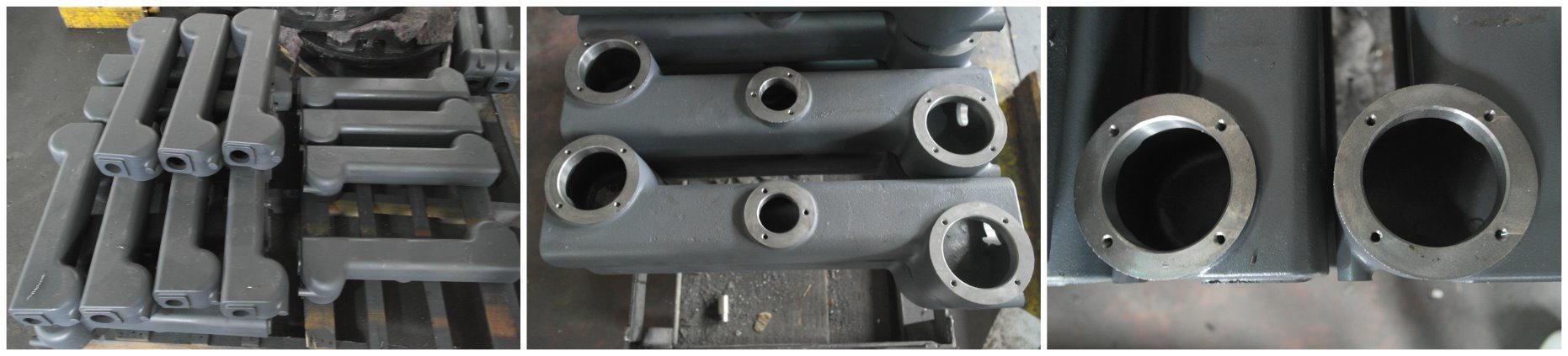

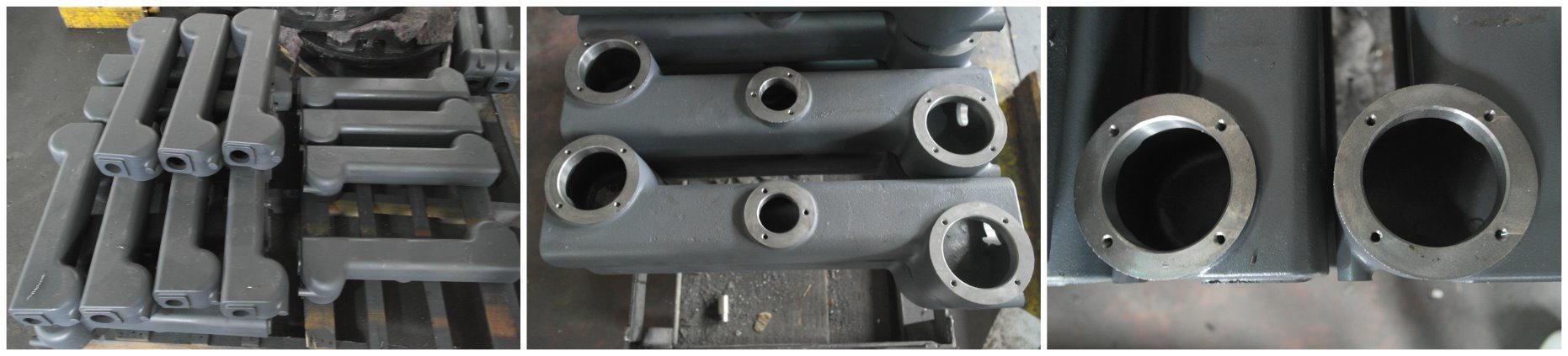

OEM/Customized Metal/Steel/Iron Pump/Valve Sand Casting Parts with CNC Machine Machining

Specifications

1. Selected material

2. Process: CNC machining

3. Smooth surface

4. ISO certified factory

5. Accept small OEM trial order

6. Over 15 experience

7. High quality and competitive price

8. One -stop service!

Our products have been exported to Japan, Unite States, South Korea and Europe for almost seven years.

Our leading products are a variety of models and specification of ball valves, pipe fitting's parts, meters'parts, flow meters' parts, surface treatment and so on.

We can support sample avaliable and we have OEM manufacture exprience for seven years.

Service Principles: Cheap, Efficient and Customer-oriented

Advantages: Custom medical precision parts high demand parts precision machining hardware

casting,foundry,die cast,aluminium casting,aluminium die casting,precision castparts,castparts,precision castparts corp,forging parts,plastic part,precast,permanent mold,lifecasting,metal parts,precision parts,diecasting,resin mold,plastic parts,lost wax,casting parts,casted meta,casting manufacturing,casting metal,metal castings,mould casting,die cast parts,die casting parts,foundry casting,aluminum foundry,die cast metal,casting manufacturers,molding casting,lost wax casting,aluminum casting,cast metal,low pressure casting,investment casting

3)Manufacturing process

1. Sample or Drawing by customer

2. Tooling proposal&Discussion

3.3D Tooling Design

4. Tooling production

5. Rough parts manufacturer

6. CNC Machining

7. Fitting&Finish

8. Tooling Measurement&Check

9. Assembly

10. Trial Production

11. Correction

12. Final Trial

13. Samples Inspection

14. Sample Approval by customer

15. Tooling Approval

16. Ductile iron sand casting

Cast/Ductile/Grey Iron Resin Coated Sand Casting Parts with Green Sand Casting Process

Quality First, Price Best, Service Foremost!

We assure you of ourbest services at all times!

| 1 | Material | cast iron, gray iron, ductile iron, steel, stainless steel, brass, copper,

aluminum, zinc etc,, |

| 2 | Process | sand casting, precision casting, investment casting, lost wax casting, die casting, forging,

stamping, machining, etc. |

| 3 | Machine | lathe, CNC, drilling machine, milling machine, boring machine, planting machine, machining

center etc. |

| 4 | Tolerance | casting:0.5mm, machining:0.05mm, finish machining:0.005mm |

| 5 | Capacity | max diameter:1M, max weight:200KG |

| 6 | Surface treatment | powder coating, painting, spraying, galvanization |

| 7 | Standard | JIS, ANSI, DIN, BS, GB |

1. Q: Why choose Ru

nner product?

A: We Runner have our own plant-- Qingdao Runner machinery Co.,Ltd, therefore, we can surely promise the quality of every product and provide you comparable price.

2. Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

3. Q: Do you provide customized metal mould casting products?

A: Yes. Customers give us drawings and specifications, and we will manufact accordingly.

4. Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there is anything we can help, welcome to contact me anytime!

Set up in 2006 and located in Weifang New Automobile Industrial Park, Which is a professional company of designing, developing, and producing of all kinds of machinery parts and its trading department is located in Huangdao District, Qingdao.

We're entitled with the following advantages:

1. Professional CNC Machining Part and Sheet Metal Fabrication manufacturer with over 7 years experience on OEM customized processing and 5 years of exporting experience.

2. With more than 100 qualified employees and 6000M2 standard workshop, our production capacity can be guaranteed, which is able to satisfy customer's diverse needs, First-class technical team includes 5 machinery engineers who are excellent by using professional software, such as CAM, Power Mill, CAD, UG, etc. And processing products according to the given CAD, 3D, 2D drawing and samples

3. Advanced production equipment includes: HAAS VMC Machine; DGM turning center; WELE 5 Face Gantry Machinery Center; VINTEC HMC, Surface Grinder, Cylinder Grinder, Bending Machine, Sheet Metal Shear, Laser cutting Machine all kind of Pressing Machines etc.