MIM Materical Selection | MIM material | Density g/cm3 | Hardness | Tensile Strengh(Mpa) | Elongation% |

| Stainless Steel | 420A(HT) | ≥7.3 | ≥48HRC | ≥1600 | ≥2 |

| 440NB | ≥7.6 | ≥750HV | / | / |

| 304L | ≥7.8 | ≥120 HV | ≥180 | ≥30 |

| 316L | ≥7.9 | ≥120 HV | ≥180 | ≥40 |

| 17-4PH | ≥7.6 | 320 HV | ≥660 | ≥3 |

| Iron-based alloy | Fe2Ni06C | ≥7.5 | ≤220HV | ≤300 | ≤8 |

| Fe8Ni | ≥7.5 | ≤140HV | ≤210 | ≤20 |

| Fe8Ni(HT) | ≥7.5 | ≥400HV | ≥1100 | ≤3 |

| soft magnetic material | FeSi3 | ≥7.5 | 120~160HV | ≥300 | ≥20 |

Products most appropriate for MIM usually have the following characteristics.

Complexity: MIM allows the same design freedom as plastic injection molding which gives almost limitless shape capability. Because MIM is a molding process, additional product features do not add cost, which makes MIM ideal for combining individual parts into multi-functional products. Design rules for MIM are very close to that of plastic injection molding thereby making it easy to adapt to almost any product.

Precision: The general guideline for MIM precision of net shape features is ± 0.5% of the dimension. Certain features can be made net shape to ± 0.3%. As with any technology, higher precision equates to higher cost so relaxation of tolerances is encouraged wherever possible. Tolerances that are not capable of being met by MIM alone can be achieved through various finishing processes.

Weight and Size: MIM is best suited for parts weighing less than 100 grams with the most economical applications being less than 50 grams. However, part weights of up to 250 grams have been processed. Raw material is a key cost driver for the MIM process. MIM promotes creative ways to reduce part weight wherever possible. Similar to plastics, coring and ribs can be used to reduce weight without compromising product integrity. MIM excels at extremely small and micro-sized parts with weights of less than 0.1 gram being possible. Weight not being a limiting factor, product lengths in excess of 250 mm can be processed.

Section Thickness: Wall sections of less than 6 mm are most appropriate for the MIM process. While thicker sections are possible, this also drives up cost due to longer processing times and additional material. Alternatively, very thin sections of less than 0.5 mm are possible for MIM to achieve but are highly design dependent.

Production Volumes: MIM is a highly scalable process. Low volume of several thousand parts annually up to millions of parts can be economically achieved. A tooling and engineering investment is necessary for the MIM process similar to casting or plastics, which will normally drive the decision process for low volume products.

Materials: MIM can process a wide array of materials including Ferrous alloys, Nickel and Cobalt base Super alloys, Titanium alloys, Refractory materials, Cemented carbides, Technical ceramics and Metal matrix composites.While non-ferrous alloys such as Aluminum and Copper alloys are technically possible but they are more economically processed by other means such as die casting or machining.Please check our materials section for more information.

Applications Assistance: Indo-MIM provides comprehensive assistance to achieve the most value from the MIM process. We help with migration of existing products in both design conversions and materials selection as we well as a full range of product development services including industrial product design, FEA, rapid prototyping and laser scanning.Our Quality Certification

About MIMO

About MIMO

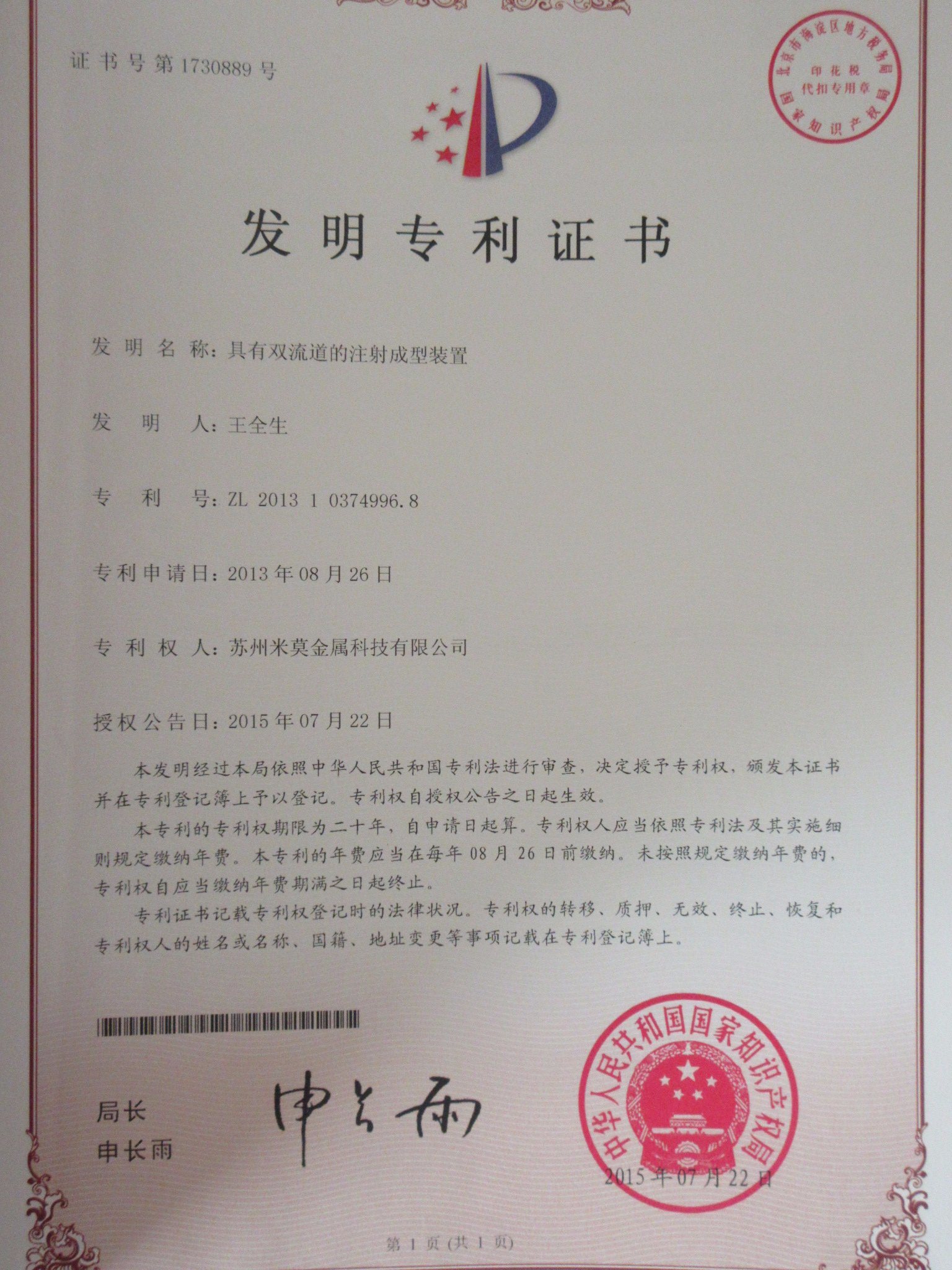

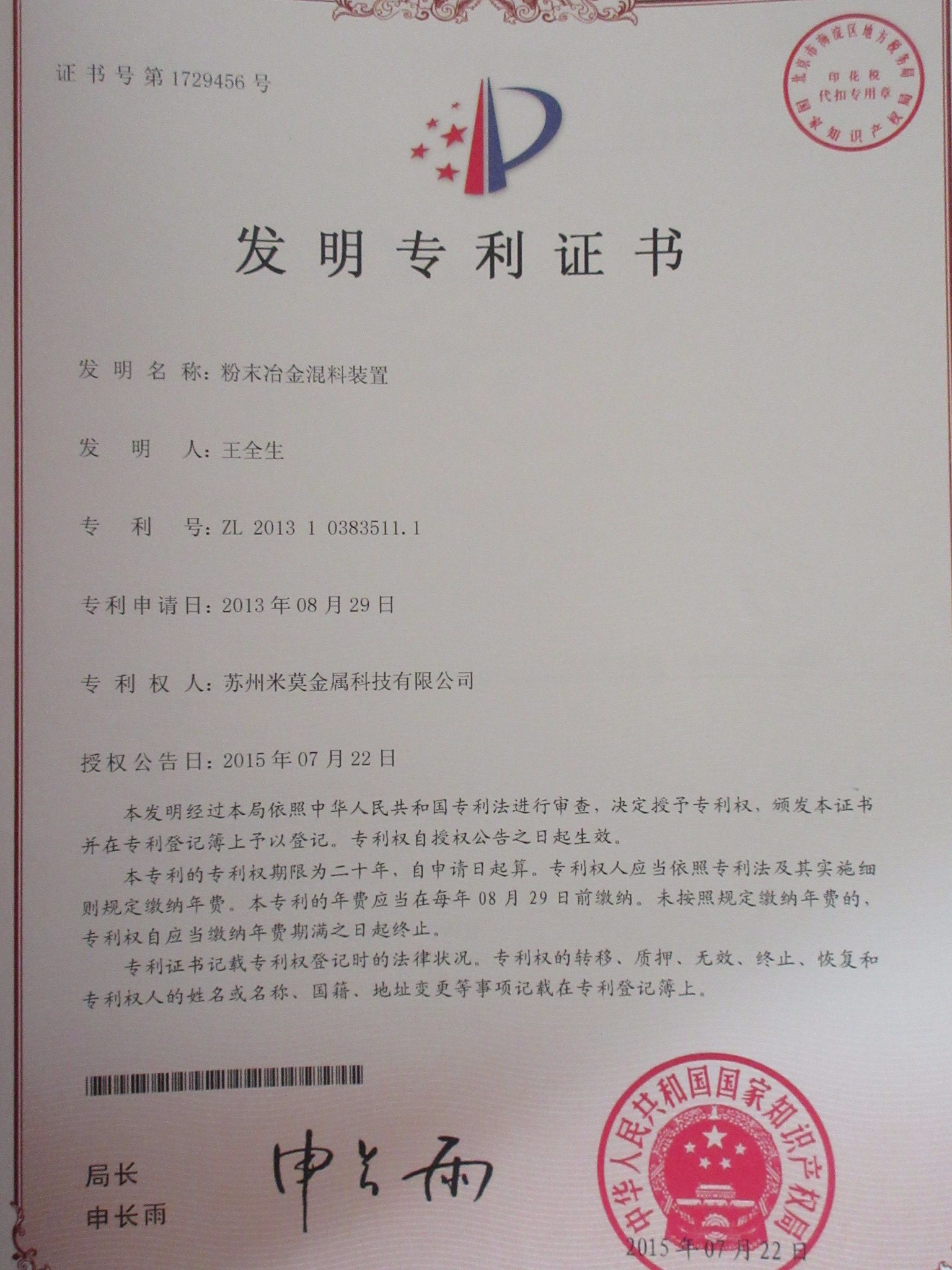

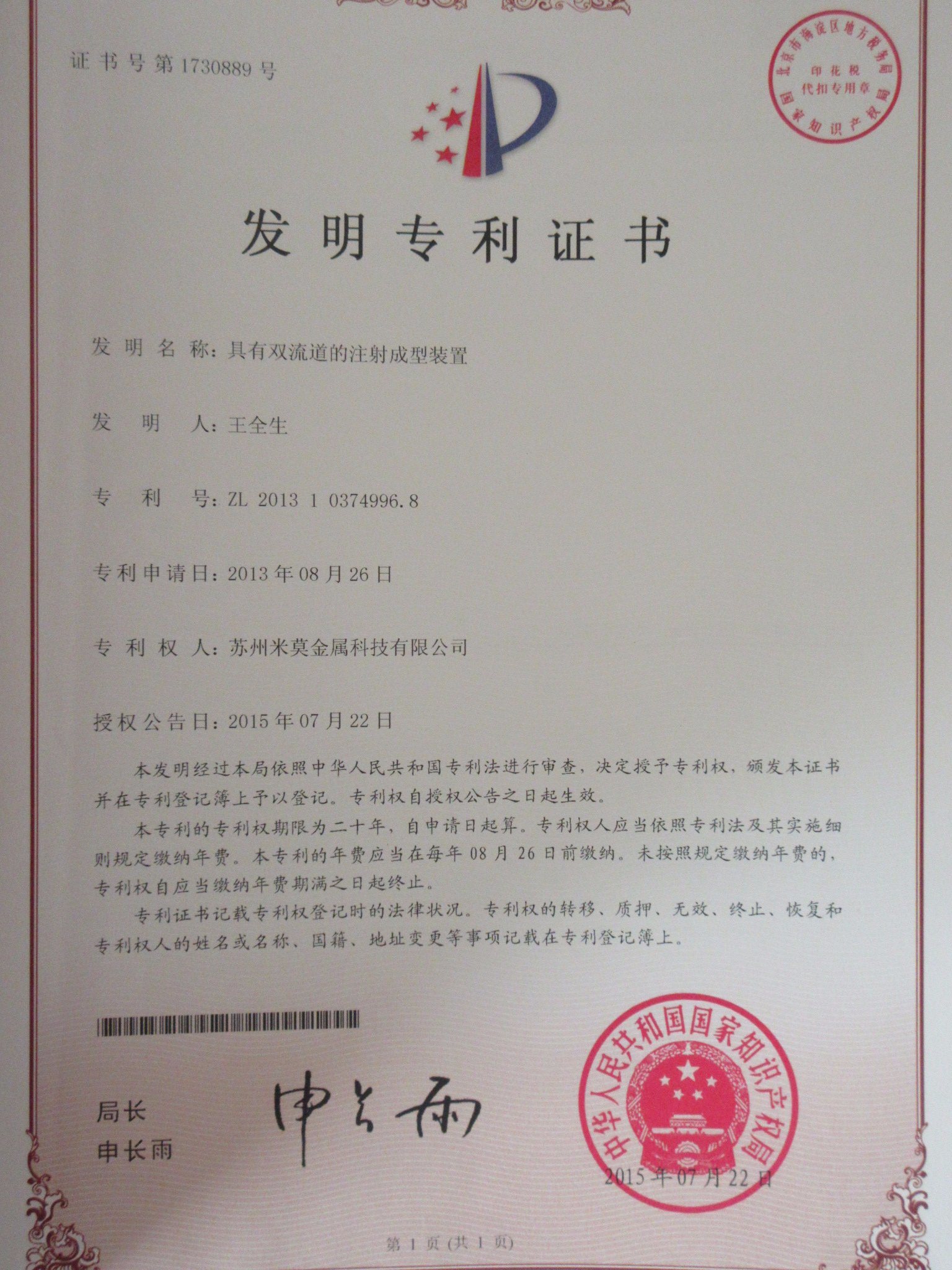

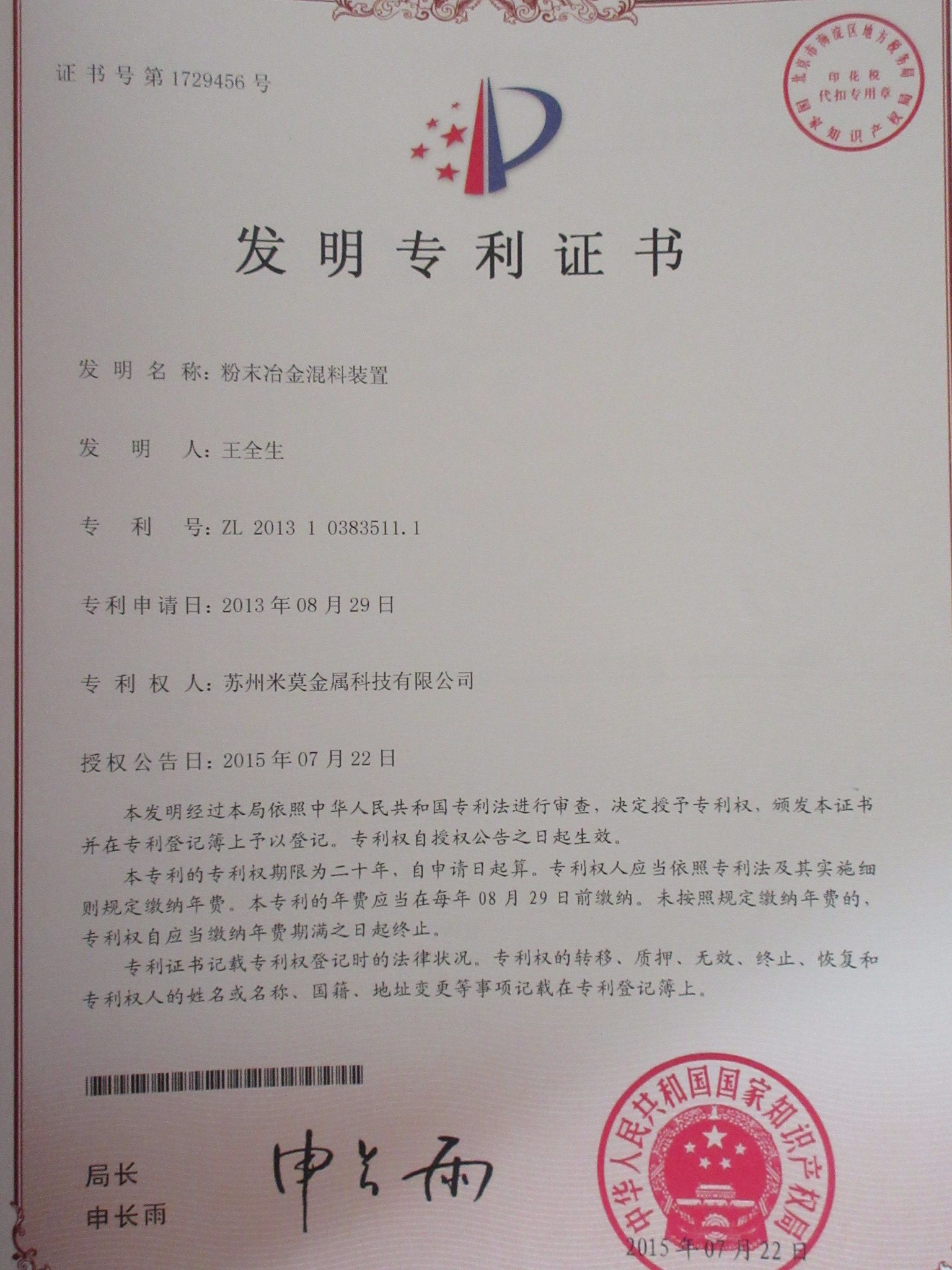

Suzhou Mimo Metal Technology Co.,Ltd. founded in 2006, is located in the beautiful Yangtze River delta - Suzhou Wujiang. Company covers an area 9500 square meters, owns mixing workshop, injection molding workshop, degreasing sintering workshop, testing center. Company has always adhere to the "scientific and technological innovation, cooperation and win-win, sincere and high efficiency, first-class service" for the service concept, use high-tech enterprises and brand building our company's future, we have professional team and mature technology, resolved to become a domestic leading professional MIM manufacturing companyContact with us in 24 hours.Aaron Sale of Jiangsu Mimo Metal Co.,LTD.

TEL:0512-63120634 Mob:+8615968841153

Web:www.mimomim.com

Address: Dong gu Road No.28 The High Shear Zone Tongli Town,In Suzhou.

Jiangsu MIMO is a leading high-tech enterprise that specialized in R&D, production and sales for Metal Injection Molding (MIM) technology. Jiangsu MIMO is located in the central of Yangtze River Delta, a geographically strategic location to make it easy for us to access customers.

Our advanced test equipment and facilities combined strength of skilled engineers, scientists, technicians and manufacturing associates, providing solid technical support for our customers. MIMO are ISO9001/TS16949/ISO14000 certified.

With the advanced MIM technology and exceptional surface treatment capability, products are being processed through plating, heating and precise grounding, and CNC workshop, which covers the whole process from product design to finished-product manufacturing. We also provide all-around services, including injection molding, insert molding and product assembly etc. We produce three-dimensional shapes of complex structural parts in material of iron, copper, alloy, stainless steel etc. In eight years, MIMO has accumulated a large number of customers all over the world.