Merid Machinery Part Metal Stamping Parts

| Price: |

US $ 0.5-399/Piece |

| Min Order: |

5000/Piece |

| Pay Type: |

L/C,T/T,D/P,Western Union,Paypal |

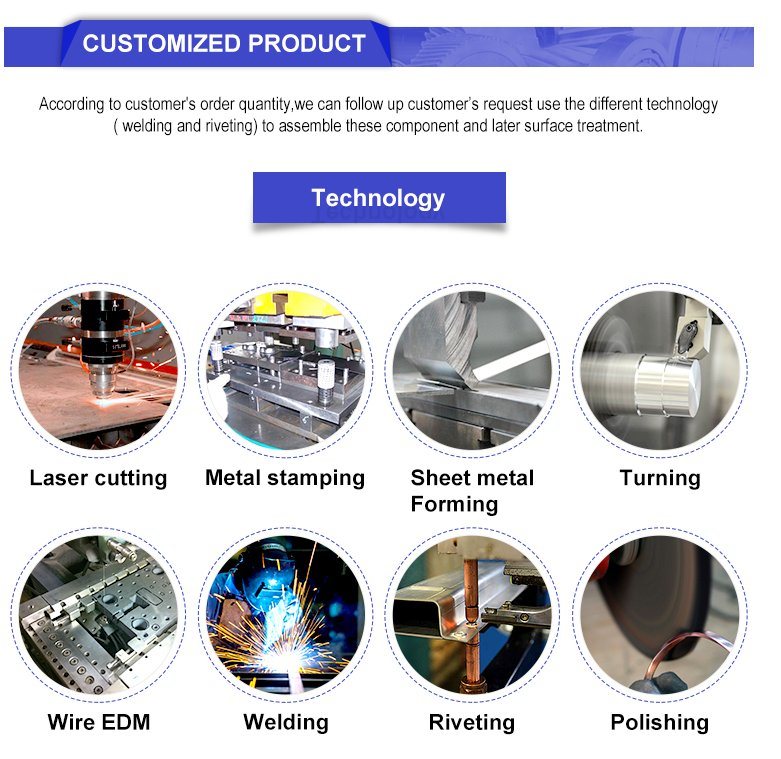

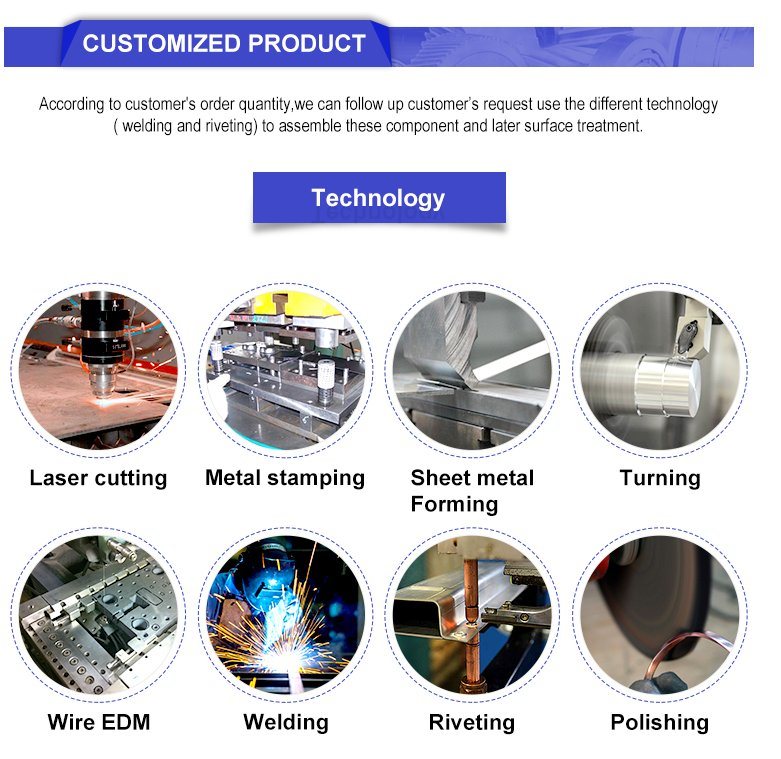

Customized Stamping Parts,Shandong Metal Stamping,China Manufacturer High Quality OEM Stamping Part Feature of Stamping parts:1.Precision Stamping parts strictly according to customers request drawing;2.Tolerance:Could be in +/- 0.02mm;

3.Quality assurance in accordance with ISO9001;

4.Experienced technology engineers for 30 years & Well tranined workers;

5.Production line is very professional with the special process;

6.Fast and timely delivery:Speedly & Professional servie;

7.Stamping Series: Stamped part, guard board, precision metal stamping, pressing parts with powder coated, pressing and welding parts, pressing and streching parts, pressing parts with glanvized.

8.Porcessing: Stamping, punching, bending, welding, threading, grinding ,milling, machining, lathe,assembling etc.Products Description:| Item name | Metal Parts |

| Manufacturer | Merid Machinery with advanced technology,professional skill and experienced technicians to fit our customers requirements. |

| Material | Iron, Aluminum, Carbon Steel, Brass, Stainless steel |

| Design | Use the advanced mould design software |

| Surface Treatment | self-color, galvanized,polishing,Zinc, powder coating, painting, nickle, chrome, polish, e-coating |

| Price Term | FOB QINGDAO |

| Delivery Time | 25-60 days based on the different products |

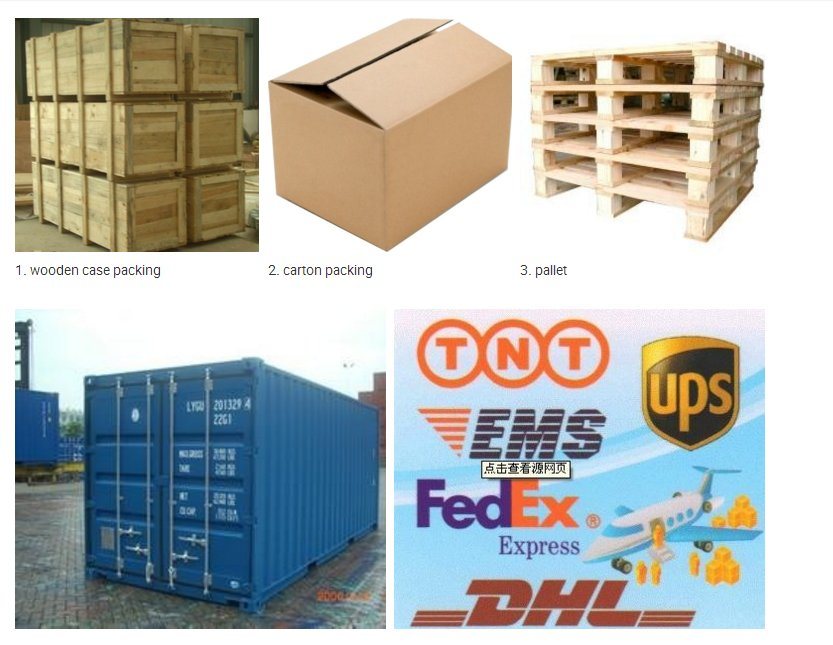

| Package | Caton,Wooden Case or as Required |

| Industry | Customized parts are used in Building,Automotive,Electrical,Machiner assembly,Furniture,Aoil field Equipments,Marine equipments,Agricultural Machines,Transportation Equipment,OEM/ODM Electronics......... |

The other products:

QC:

QC:

Company information:Qingdao Merid Machinery Co.,Ltd was established in Qingdao, China in 1983, with and area of 10,000 square feet. We are a professional top provider and industrial leader of full-service stamping, welding, machining, die castings and fabrication of metal components.The fields covers:

Company information:Qingdao Merid Machinery Co.,Ltd was established in Qingdao, China in 1983, with and area of 10,000 square feet. We are a professional top provider and industrial leader of full-service stamping, welding, machining, die castings and fabrication of metal components.The fields covers:

1.Automotive parts

2.Medical parts

3.Agricultural parts

4.Stock farming parts

5.Architectural parts

6.Industrial parts

7.Special Fields

8.Energy Industry

9.Telecommunication

10.Optical Semi-Conductor

11.Appliance

12.Lighting

13.AerospaceMerid is equipped with the in-house capabilities of taking your project from design - tooling - prototype - production to finish, and the professional technical and production team could provide you the best solutions to ensure high quality and cost effective production of your products,

In 2008 Peter assumed responsibilities as President, still holding dear to his vision of embracing technology to ensure customer satisfaction. During the next 10 years, Peter continued looking at the product being made and researched othertypes of equipment to better manufacture the product we were providing our customers. The management team was also enhanced with other seasoned industry professionals. Machinery work times per day:

Machinery work times per day: | | 220T Press Machine | 160T Press Machine | 80T Press Machine | 63T Press Machine | 35T Press Machine |

| Work times per day | 6000 | 8,000 | 13,000 | 18,000 | 30,000 |

Market: | Main Markets | Total Recenue(%) |

| Europe | 18 |

| America | 16 |

| Domestic Market | 13 |

| Eastern Asia | 12 |

| Mid East | 21 |

| Africa | 20 |

Package: FAQ:

FAQ:

1.What are our advantages over others?

a). Stamping, Machining, Welding, Die casting and Surface treatment equipment are equipped for providing you our best service and solutions.

b). 45 years experience.

c). On-time delivery.

e). Strict Quality Control System: 100% inspection before the shipment.

.

2.What are the production capacity of your company?

a). In Merid, fabrication works include precision stamping, deep drawing, fine blanking, cnc punching, cnc bending, laser cutting, flame cutting, cnc milling, cnc turning, tube bending, aluminum extruding, welding, die casting, etc.

b). Metal materials include stainless steel, iron, carbon steel, spring steel, aluminum, titanium, copper, brass, bronze etc.

3.What equipments do you own?

a). Punch Press: 16T-400T.

b). Welding: Carbon dioxide welding, spot welding, tig welding, automated robotic welding.

c). Machining: CNC lathe and machine centers, light machines(drilling, milling and tapping).

d). Die casting: 80T-500T.

e). Surface treatment: Shot blasting facility, Polishing, Deburring.

4.What finishes can you provide?

The finishes which we could provide is powder coating, painting, galvanizing, baked enamel, anodizing finish, and other plating finishes.

5.How can you guarantee the quality?

Quality control department build the control plan before starting the project, the strict inspection will be applied throughout the whole production.Contact:Tel:+86 18678963713

| Prod Model: |

customized |

| Brand: |

Merid |

| Payment: |

T/T, L/C, Western Union |

| Package: |

Carton or According Customers Prime; Requirement |

| Delivery Time: |

7-50 Days |

| Quality Control: |

0 Defects, 100% Inspection Before Packing |

| Application: |

Contruction |

| Name: |

Stamping Componets |

| Logistics Service: |

Sea, Air, Express, EXW, Fob, CIF, DDU, DDP |

| Design: |

Ccording to Customers Requirement |

| Machine Type: |

16t-220t |

| Process: |

Separation Process |

| Industry: |

Metal Stamping Parts |

Qingdao Merid Machinery Co., Ltd was established in Qingdao, China in 1983, with and area of 21000square feet. We are a professional top provider and industrial leader of full-service stamping, welding, machining, Castings and Forging of metal components.

The fields covers:

*Automotive parts

*Medical parts

*Electronics parts

*Agricultural parts

*Stock farming parts

*Architectural parts

*Industrial parts

Merid is equipped with the in-house capabilities of taking your project from design - tooling - prototype - production to finish, and the professional technical and production team could provide you the best solutions to ensure high quality and cost effective production of your products.

Our strong team is dedicated to providing you the world-class quality and service, our team includes professional engineers and designers, skilled tool makers, experienced QC inspectors, well-trained machinists and management personnel.

Today, we continually invest in efficient technologies, new capabilities and develop our people to the best in the industry. At Merid, our mission is to strive for the perfection. We promise maintain our integrity with customers and employees, meanwhile the high ethical standards and complete commitment to 100% meet customer's satisfaction.

Through nearly 45 years of service, Merid has become a leading manufacturer of custom metal parts. We have served more than 30 countries and regions throughout the world by providing quality custom parts timely at a fair price and top-level service.

With Strong capabilities, good reputation, professional service, and the concept of a win-win solution, we are willing to work with the clients from all over the world to share the mutual benefit and common development.

Qingdao Merid Co., Ltd will remain honest and pragmatic as always to safeguard, strengthen and carry forward our National Brand, provide quality commodities and top-class services to domestic and overseas clients. We sincerely wish to develop long-term win-win cooperation with domestic and overseas clients. Welcome customers from all over the world contacting us and start our cooperation.