Hot Forging Tube Forging Cylinder 35CrMo for Machines Parts

| Price: |

US $ 500-600/Ton |

| Min Order: |

1/Ton |

| Pay Type: |

L/C,T/T,D/P |

Product DescriptionDescription:Hot Forging Tube Forging Ring 35CrMo for Machines Parts

Material:Steel

Specifications| 1.Product name: | Hot Forging Tube Forging Ring 35CrMo for Machines Parts |

| 2.Material | AISI1045,,AISI4140,AISI4130,AISI4340,4317AISI,AISI4130,AISI8620,9840AISI,AISI4145H

AISI4145H,AISI4145HMOD4330vAISI,AISI4330vMOD,4150AISI,AISI1020,30CrMo,35CrMo

20CrNiMo,42CrMo4,25crmo4,34CrNiMo6,17CrNiMo620nicrmo22-4,34CrMo4,30CrNiMo8

,36CrNiMo4,16crnimo12,,40nicrmo7,41cralmo7,30nicrmo12,12crmo9-1018crmos4

,18CrNiMo7-6,17CrNiMo6,,16MnCr5,ST52-3,S355J2G3,50crmo4,39nicrmo3,,20Nicrmo2-2 |

| 3.Dimension | Weigh 2T-55T |

| 4.Standard | AISI,GB,ASTM,BS,JIS,NF,DIN |

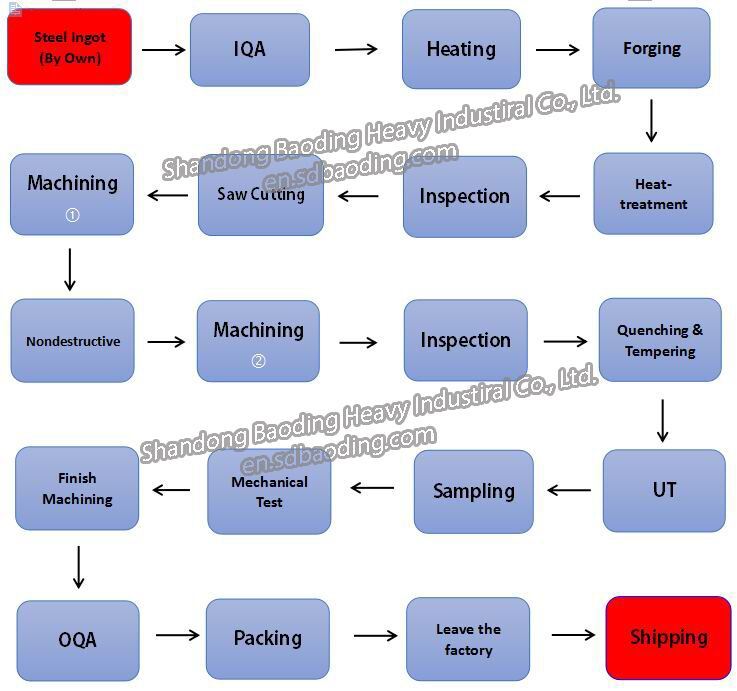

| 5.Forging processing | Quality raw materials recycling---Electric arc Furnace---LF Furnace---VD Furnace---VC---Steel Ingots---Heating---Forging---Rough Machining---Heat Treatment |

| 6.Heat treatment | Normalized / Annealed / Quenched / Tempered |

The product can be provided as per your drawing or specified requirements.Specifications| Material | C | Si | S | P | Cr | Mn | Mo | Ni |

| 35# | 0.32~0.40% | 0.17~0.37% | =<0.035% | =<0.035% | =<0.25% | =<0.25% | -- | -- |

| 45# | 0.42~0.50% | 0.17~0.37% | =<0.035% | =<0.035% | =<0.25% | =<0.25% | -- | -- |

| 30CrMo | 0.26~0.33% | 0.17~0.37% | =<0.030% | =<0.025% | 0.80~1.10% | 0.40~0.70% | 0.15~0.25% | -- |

| 35CrMo | 0.32~0.40% | 0.17~0.37% | =<0.035% | =<0.035% | 0.80~1.10% | 0.40~0.70% | 0.15~0.25% | -- |

| 42CrMo | 0.38~0.45% | 0.17~0.37% | =<0.035% | =<0.035% | 0.90~1.20% | 0.50~0.80% | 0.15~0.25% | -- |

| 20CrNiMo | 0.17~0.23% | 0.17~0.37% | =<0.035% | =<0.035% | 0.40~0.70% | 0.60~0.95% | 0.20~0.30% | 0.35~0.75% |

| 34CrNiMo | 0.30~0.38% | =<0.40% | =<0.035% | =<0.035% | 0.80~1.10% | 0.40~0.70% | 0.15~0.30% | 1.40~1.70% |

Production Process:

(Raw materials are processed by ourselves.)

Company Introduction Shandong Baoding Heavy Industrial Co., Ltd is located in Qihe Economic Development Zone, Dezhou City, Shandong Province, covering an area of 333,000 square meters and 11km away from Jinan, the provincial capital. With a registered capital of RMB 100 million and total investment of over RMB 1 billion, the Company now has more than 460 employees and 54 technicians, including 18 senior engineers, 3 senior accountants and 33 engineers. The Company mainly possesses 65 (sets of) large-scale manufacturing facilities, including 100t electrical arc furnace, 120t ladle furnace, 120t vacuum degassing furnace and 120t vacuum casting system, several infrared heat-treatment furnaces and efficient dust removal, waste heat recovery and water treatment systems, etc. In addition, it also has stainless steel production system of 50t VOD furnace and 50t AOD furnace, as well as forging machines, including 6300t hydraulic unit, 3150t German high-speed forging hydraulic press units, 50t and 100t high-speed forging manipulators, 28 large natural gas soaking and annealing furnaces, several machine tools for machining, such as lathe, milling machine, sawing machine, planning machine, grinding machine, and 8t free forging electro-hydraulic hammer, etc.Main ProductsThe Company mainly produces high-strength large precision alloy casting, high-end mold steel, steel forging for ship, supplies for high-speed rail and deep water oil drilling, etc. which contain nickel, chromium and molybdenum.

Product category mainly includes stainless steel casting and forging, oil valve, steel for offshore oil, casting and forging for large electric power-generating equipment basic parts and ships, large steam turbine rotor, various wind power main shafts, gear parts of bullet train transmission shaft, casting and forging for large mold and various wear resistance guide plate, large gear and gear ring, large ring rolling of various ring rolling machines, high-speed train axle, large axles for ships, large axles of machine tool, forged round bar up to 1.6m in diameter and final product processing & delivery of various large castings and forgings.

| Prod Model: |

steel cylinder |

| Processing Object: |

Metal |

| Molding Style: |

Forging |

Shandong Baoding Heavy Industrial Co., Ltd. Was founded in December, 2010.

Covering an area of 333, 000 square meters, the provincial capital. With a registered capital of RMB 100 million and total investment of over RMB 1 billion.

We are manufacturer, could according to customer's drawing quote precisionly. (Raw materials are processed by ourselves)

I. Manufacturing Facility and its Capacities

The Company mainly possesses 65 (sets of) large-scale manufacturing facilities, including 100t electrical arc furnace, 120t ladle furnace, 120t vacuum degassing furnace and 120t vacuum casting system, several infrared heat-treatment furnaces and efficient dust removal, waste heat recovery and water treatment systems, etc. In addition, it also has stainless steel production system of 50t VOD furnace and 50t AOD furnace, as well as forging machines, including 6300t hydraulic unit, 3150t German high-speed forging hydraulic press units, 50t and 100t high-speed forging manipulators, 28 large natural gas soaking and annealing furnaces, several machine tools for machining, such as lathe, milling machine, sawing machine, planning machine, grinding machine, and 8t free forging electro-hydraulic hammer, etc.

II. Main Products

The Company mainly produces high-strength large precision alloy casting, high-end mold steel, steel forging for ship, supplies for high-speed rail and deep water oil drilling, etc. Which contain nickel, chromium and molybdenum.

Product category mainly includes stainless steel casting and forging, oil valve, steel for offshore oil, casting and forging for large electric power-generating equipment basic parts and ships, large steam turbine rotor, various wind power main shafts, gear parts of bullet train transmission shaft, casting and forging for large mold and various wear resistance guide plate, large gear and gear ring, large ring rolling of various ring rolling machines, high-speed train axle, large axles for ships, large axles of machine tool, forged round bar up to 1.6m in diameter and final product processing & delivery of various large castings and forgings.

III. Scientific Results and Certifications

After setting up a scientific center with complete functions, the Company has obtained 14 patent technologies, such as water-cooled ingot mold, able to produce extremely thick and wide, square and flat, extra-large ingot whose proportion of equiaxed grain is about 30% larger than that produced with traditional ingot mold, therefore, ingot quality is improved significantly. Ingots produced with the patent technology of ingot mold without riser have an about 5% yield higher than traditional ingot, and create a favorable steel rolling condition for large-scale rolling process with extremely thick plate rolling mill.

The scientific center is equipped with metallographic electronic microscope, spectrometer, H/O/N gas analyzer, Heraeus hydrogen determinator, CS analyzer and other physical test machines, which can conduct tensile, low temperature impact, Vickers, Brinell and Rockwell hardness test, yield strength and other physical experiments, as well as ultrasonic flaw detection and high- and low-magnification microstructure analysis etc.

The Company has passed ISO9001 quality management system certification, ISO14001 environmental management system certification, OHSAS18001 occupational health and safety system certification, Shandong Province high-tech certification; Some products passed certifications of German, American, Norway and China Classification Societies. What's more, the Company was rated as National Laboratory, Shandong Province Technological Research Center, Advanced Unit of Environment Protection and Advanced Enterprise of Tax Payment, and obtained Production License of Pressure Vessel.