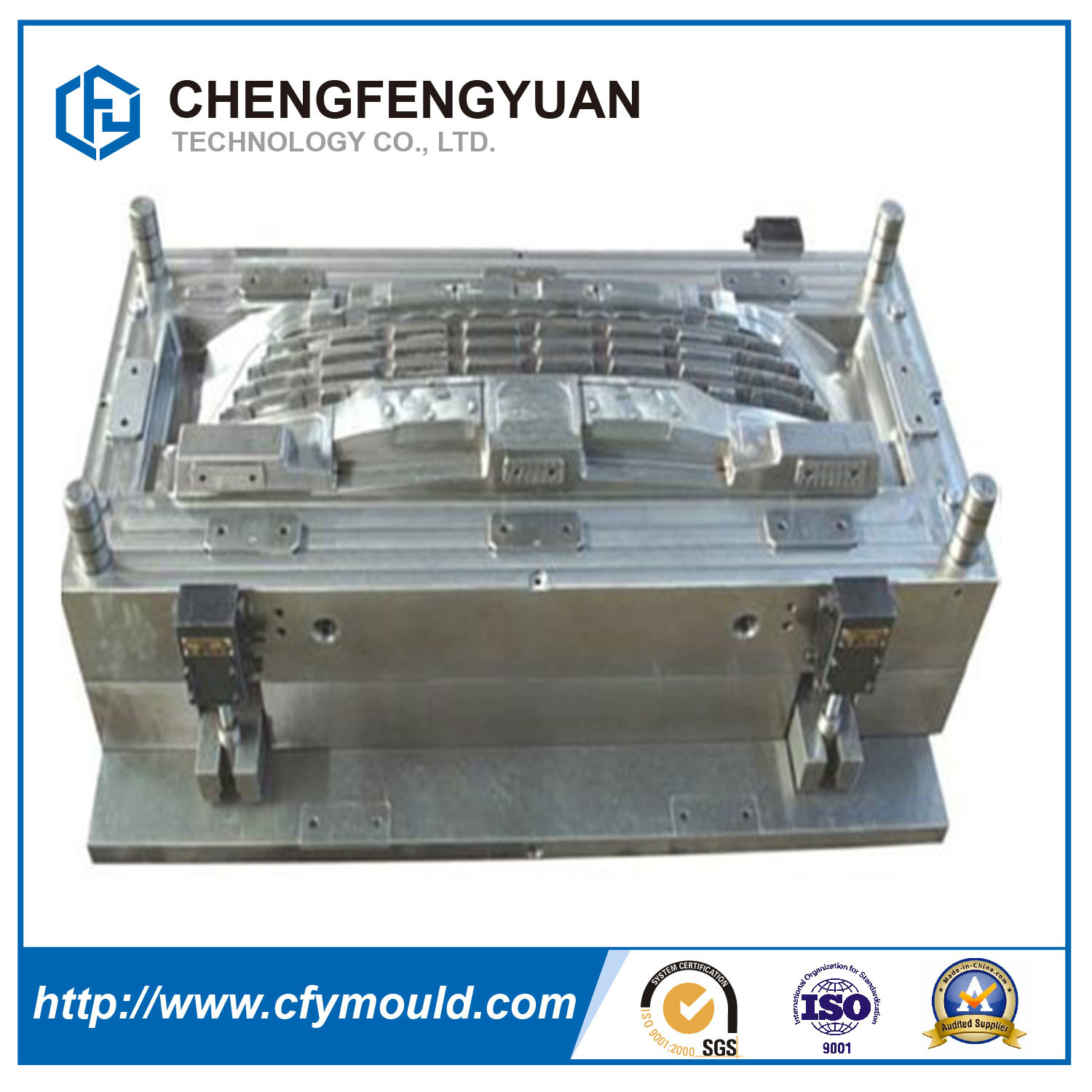

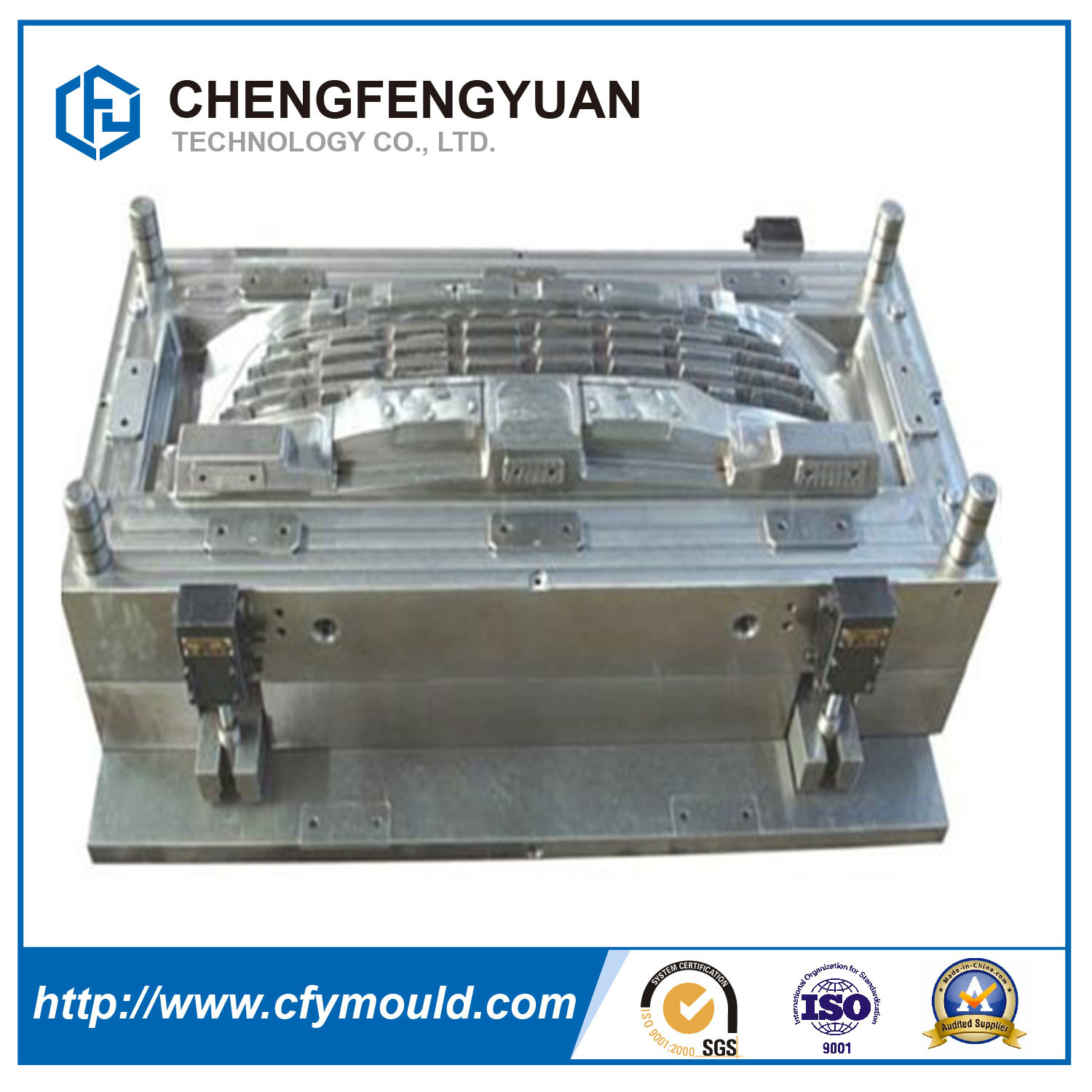

Plastic injection part/ plastic injection molding

| Working Process | Plastic injection molding,plastic welding,assembly, |

| Material | PA6,PA66, ABS, PC, PP, PS, POM, PMMA, glass fibre filled pA6,etc,

Can meet drawing's requirement. |

| Mould Base | LKM, FUTA, HASCO,DME, etc.Or as per customer' s requirement. |

| Mould treatment | Sand blasting, texture, polishing, discharge extinction, etc. |

| Product Surface treatment | Electroplating, spray coating, vacuum plating, printing. |

| Color | Can be meet customer's requirement. |

| Sample lead time | 15-25 working days |

| Packing | Inner-Plastic Bag;Outer -Standard Carton Box. |

| Application | Medical and Paramedical Device,Communications,Automobile,

Electronics, electric appliance, Defence Equipment,Food machinery |

| Cavity Number | Single cavity,Multi Cavity,or based on customer' s requirement. |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF. |

| Service | Quick response and immediate action provided by the export sales

And professional engineer team supporting |

| Inspection | IQC, IPQC,FQC,QA |

Detail About CFY Technoly Co.,Ltd.

Detail About CFY Technoly Co.,Ltd. Chengfengyuan Technology Co., Ltd. (CFY), a wholly-owned enterprise and Chinese direct manufacturer, was founded in January 2008, The company has passed ISO9001: certification.

The company mainly produces sheet metal, plastic injection mould, power cabinet, chassis, cabinets, network cabinets, advertising cabinets, computers, die casting, communications and other products supporting hardware, assembly, etc. We have also R&D of metal mould design and manufacturing, as well as various types of metal stamping parts, LED frame, rear shell, metal base.

Packing and Shipping

FAQ

FAQ

1. Are you manufacturer or trade Company?We are a factory founded in 2008 with trade team for international service.2. What terms of payment you usually use?T/T 30% deposit and 70% against document, Western Union, L/C at sight3. What is your lead time for your goods?Normally 35 days after confirmed order. 30 days could be available in low season for some items (during May to July), and 45 days during new year and hot season ( Jan to March).4. SamplesFor customers who need sample confirmation before ordering, please bear in mind that the following policy will be adopted:1) All samples are free of charge with the maximum value not exceeding USD 100.2) The courier cost for the first-time sample sending will be charged for by the consignee. We will send the samples with freight to be collected. So please inform your account with FedEx, UPS, DHL or TNT so that we can proceed promptly.3) The first-time courier cost will be totally deducted from the contract value of the trial cooperation.5. Order Process | 1.Sample/Drawing | We need your detail require clearly. |

| ↓ | |

| 2.Negotiation | Material,cavity,price,delivery time,payment term ,etc. |

| ↓ | |

| 3.Place order | According your own design or choice our design. |

| ↓ | |

4.Mould design

| We will communicate&Exchange the opinion with you during making drawing |

| ↓ | |

| 5.Tooling mould | After custome approve the mould design will start making mould. |

| ↓ | |

| 6.Mould process | Provide photos for customer show them tooling process |

| ↓ | |

| 7.Sample confirm | Send you sample for confoirm it ,if not satisfied by customer.we modify mould . |

| ↓ | |

| 8.Delivery mould | Delivery mould after customer approve sample and arrange shipment. |

Chengfengyuan Technology Co., Ltd. (CFY), a wholly-owned enterprise and a direct manufacturer, was founded in January 2008, The company has passed ISO9001: Certification.

The company mainly produces sheet metal, plastic injection mould, power cabinet, chassis, cabinets, network cabinets, advertising cabinets, computers, die casting, communications and other products supporting hardware, assembly, etc. We have also R&D of metal mould design and manufacturing, as well as various types of metal stamping parts, LED frame, rear shell, metal base and etc.

We are adhering to the service concept that quality first, customer satisfaction, the pursuit of innovation, sustainable development. Chengfengyuan(CFY) not only abide by laws and regulations, but also to prevent environmental pollution as well as participates in environmental protection in order to reduce pollution and waste reduction. "Excellent quality with reasonable price is our strong guarantee. Positive cooperation, sincere service is the purpose of the business enterprise. To meet the needs of our customers is our constant commitment. The Chengfengyuan(CFY) has become a qualified supplier as the products have been recognized by more and more domestic and foreign well-known customers. We look forward to establish friendly and cooperative relations with the customers all over the world.