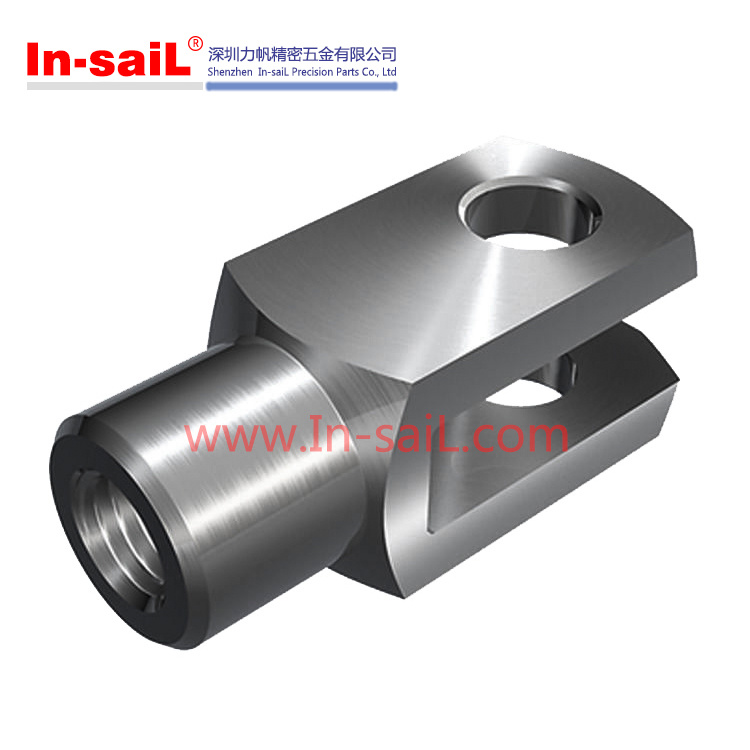

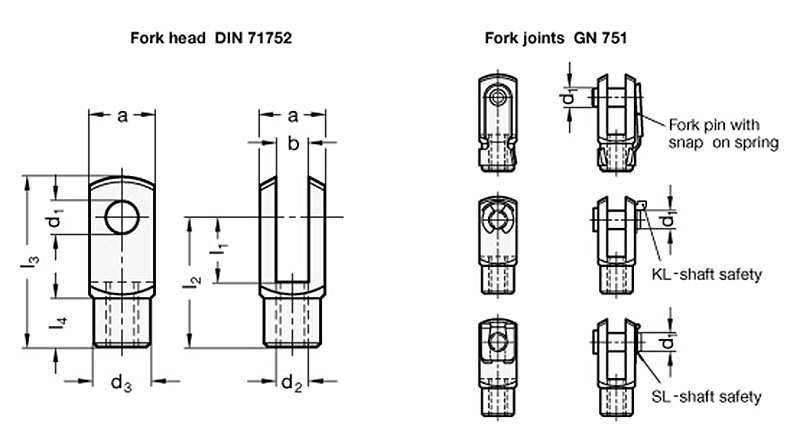

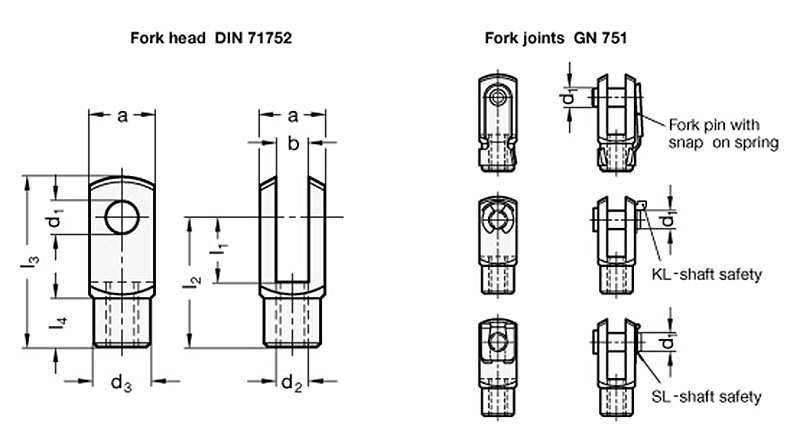

DIN 71752 DIN ISO 8140 Stainless Steel Clevis

Company ProfileQuality is our cultureA trustworthy partnerAs some of the most frequently used linking elements in the industry, the Clevis joints DIN 71751 (or similar) can be found everywhere where simple movements are needed, such as linear pushing, pulling or axle offset compensation.

Clevis joints include corrosion-resistant clevises in order to eliminate material damage caused by corrosion from the outset. Depending on the choice of material, they can also withstand aggressive media or ambient conditions. The service life can be significantly prolonged as the clevises are made from nickel-chromium steel of 1.4305 or 1.4404 grades (seawater-resistant). This even works under problematic conditions and the user is guaranteed of having a high degree of production reliability. The bolts and retainers which are also included in the product range can be used to complete the preassembled clevis joint.

Company Profile

In-sail/Sandum is dedicated to manufacturing of precision components and the design, fabrication of engineering specialty fasteners and fastening solution development.

Manufacturing Capability

We have powerful manufacturing capability, our automatic lathes, CNC lathes, CNC machining centers, stamping machines and cold heading machines plus auxiliary equipments like milling machine, grinding machine, EDM and the cooperation of our partners, we are able to support every different components regardless of the prototyping or series production.

Auto Lathe Turning

The single shaft cam-base automatic lathes are capable of massive production of brass, aluminum alloy, stainless steel components.

Production range: O. D. 0.5-15

CNC Milling

4-axis and 5-axis machining centers are capable of complex structural parts.

Production range: 800x600

Screw Heading & Rolling

The screw production lines finish the cold heading and thread rolling for small carbon steel or stainless steel screws.

Production range: M0.8-M6 or equivalent sized imperial screws

Stamping

Stamping machines perform the blanking, punching, blending, drawing. Currently we are working on simple stamping jobs.

Production range: 200T max.

| Material | Aluminum alloy,Brass,Stainless Steel,Carbon steel,according to customer's requirement |

| Finish | Milled /Tin plating, copper-plating,hot-dip galvanizing, black oxide coating,red anodized,black anodized,painting,

powdering,rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Testing Equipment | CMM,Projector,Pull Tester,Automatic Optic Inspector,Projecting apparatus

Salt Spray Test, Durometer, and Coating Analyzer,Tensile Machine |

| Management System | ISO9001:2008 |

| Certification | SGS,RoHS,Material Certication,PPAP |

Production Capability

| Auto-lathe turning:ODΦ0.5-20mm,Tol.±0.01mm |

| CNC lathe turning:ODΦ0.5-250mm,Tol.±0.005mm |

| CNC Milling:800x600mm(LxW),Tol.±0.05mm |

| Grinding:Tol.±0.002mm |

| Screw heading & rolling:Metric 0.8-M6,Unified Imperial#0-1/4'' |

| Stamping:200T max |

| Lead Time | 5-15 working days |

| Samples | Welcome |

| Delivery term | By DHL,UPS,TNT,FedEx,EMS,By Ocean,By Air |

| Warranty | Replacement at all our cost for rejected products |

Product Details:

1.Standards:DIN, GB, BS, ANSI, ASME,JIS,ISO

2. Material:Stainless steel(SS304,SS316), carbon steel(C1022,1010,1008) copper, iron and so on.

3. Size: ST 2.9-6.3 #6--#14

4. Certificate: ISO9001:2000 RoHS certification

5. Features:Good anti-corrosion ability, kinds of coatings

6. Grade:4.8, 6.8, 8.8, 10.9, 12.9 A2-70 A4-80...

7. After-sale service:If any quality problem, we will do our best to help you.

8. Surface treatment: Black oxide, zinc plated, chromium, and according your requirement

9.Packing:Bulk(25kgs/carton) or small package(according to the customers' requirement and the size)

10.Usd fields: Construction industry, furniture fields and other public equipment

We have the following types of equipment:

1.Conventional and CNC Lathes and auto lathes

2.Conventional and CNC Milling Machines

3.High Speed CNC Machining Centres

4.4-axis CNC Machining Centres

5.Precision Wire Cut Machines

6.Surface and Cylindrical Grinders

We also perform various heat treatment processes and metal finishing, chrome, nickel plating and anodizing

Our advantage:

1. Experienced technical staff

2. Product warranty

3. Prompt delivery

4. Quality approval

5. Small order accepted.

6. Competitive price

7. First-class service

Packing method:

Can provide various sizes and packing according to specific requirements

Packing material: PP bag, copy paper, carton, wooden box, pallets

Meet export requirement

According to customer's required

We have many years of experience in the production of OEM, and we have developed products known for quality and service. Look forward to cooperating with you!

In-saiL & Sandum (China) Operation Center is part of Leasan Enterprise Group. Group since 1982 in Taiwan, has always insisted quickly and accurately provide a variety of high-quality parts fastening systems, automation parts, electronic hardware, mold parts, machine tools and other parts to customers. Group has committed to R & D and innovation, the core technology as the center, including: Environmental process technology, precision molds technology, CNC machining technology, powder metallurgy technology. Group is not only a sound R & D management system, but also in the Intellectual Property Management to work actively to enhance the international competitiveness of the Chinese mission, and corporate social responsibility in environmental protection and energy saving, emission reduction, green, recycling and other efforts to promote and dedication;

Leasan Enterprise Group was established 33 years ago, it has established five manufacturing centers, located in Taiwan, Singapore, Mexico, Jiangsu and Guangdong. The purchase of a large number of high-precision manufacturing equipments, such as CNC lathes, CNC milling, CNC grinding machines, precision presses and injection molding machines more than 3600 sets, with the system of industrial parts manufacturing capacity. Also set up independent 3 operations center (Taiwan operations center, operations center in Singapore and Shenzhen operations center), responsible for worldwide customer's business cooperation and technical support.

In-saiL Hardware & Sandum Precision to force Leasan Enterprise Group as the basis, will focus on the quality and delivery of client work together to contribute our wisdom and strength for the development of the global manufacturing industry.