FAQ

Q:What is your well mould of business?

A. Precision Plastic Mold manufacture

B. Medium and large plastic mold manufacture

C. Injection molding

D. R&D service

E. One-stop solution from design to mold manufacture and mass production

Q:How about the tolerance?

A : Mold tolerance is 0.005 mm, Product tolerance is 0.02 mm.

Q:What standard components do you usually use?

A : We use standard components from LKM, DAIDO, HASCO, DME. (Hot Runner: MOLD

MASTER,HUSKY,DME,HASCO,INCOE,THERMOPLAY,YUDO).

Q:What do you need for quotation?

A : We need 2D part drawing & 3D drawing, and specific mold or part requirements.

2D File Format: dwg / dxf / pdf / jpg / png / gif / bmp / swf

3D Model Format: prt / asm / igs / obj / max / 3ds / ma / vtk / stl / stp

Q:Can you make double color injection mold and over mold?

Can you make insert mold?

A : Yes,we can,we have professional team and professional experience.

Q:How about your mold payment terms?

A : Mold payment terms:40%-30%-30%.The first payment is when you sign the order,you should pay us 40% of the

total value;the second payment is when you receive our sample product,you should pay us 30% of the total value;

the last payment is when we deliver the mold for you,you should pay off the balance payment,30% of the total value.

Q:What's your after sales?

A : After sales:Our customer's mold drawings and the whole data will be kept in database for 5 years at least.so that

when you need our technical support or service,we can be easy and possible to serve you and your customers

| Item Name | OEM Plastic Injection Mould for plastic parts |

| The company's strength | 1). Efficient team in exporting mould

2). Delivery on time

3). Excellent equipment

4). High quality and competitive price |

| Core & cavity material | Saarstahl, Assab, AISI & JIS, DAIDOSTEEL, ALCOA,

S136, 1.2311, 1.2738, NAK80 2344, 420, 2083 etc |

| Plastic material | ABS, ABS+PC, PP, PS, POM PVC,TPE, TPU ,Acetal, PA66

PA6, PA66+30%GF, PPS, etc |

Main processing

Equipment | CNC, wire cutting, Grinding machine, Lathe, Drill Press,

EDM center |

| Practicable software | Pro/E, UG. Solidworks, AUTO cad |

| Business Scope | 1). Plastic Mould Design

2). Mould making/Mold making/Tooling manfuacture

3). Plastic parts injection

4). Reverse Engineering

5). Rapid prototype manufacturing

6). Sheet Metal prototype manufacturing |

Primary Competitive

Advantages | 1). Quickly response and complete understanding

2). The most competitive and reasonalbe price

3). Short delivery time and prompt delivery

4). Well and High Quality Control

5). Customer's Designs and Logos are welcome |

CHINA PLASTIC INJECTION MOULD MAKER

"Listen to our customer, understand their project! " We always follow this principle, offer you competitive

price, high quality and good after services. Any of your inquiry will be highly appreciated!

We will reply you within 24 hours!

Well mould, specialize in making common custom plastic moulds, High precision moulds, High cavitation injection moulds, large size moulds, Two shot moulds, Unscrewing moulds, Gas assist moulds, Die casting moulds. Well mould is a professional plastic mould maker located in shenzhen, with 20 years experience, a skilled and well trained team of engineers and support staff.

Well mould offers a one-stop service from R&D->mould design->mould making->molding->secondary prosessing(Electro-plating, silk screen, oil spray etc)->assemble->delivery. For more information, please pay a visit to our website: www.wellmoulding.com

>R&D product

>OEM&ODM(Air purifier&Filter )

>2K mould parts()

>Automotive parts()

>Communication parts()

>Die Casting parts()

>Medical parts()

>POS terminal(POS )

We are sure our passionate and professional skills to provide service for our cusotmer fast and professional quotation.

1. DFM

->Design for manufacturability (During RFQ)

2. Mold Timing plan

->Track the mold processing weekly by time (every Thursday )

->Track the mold processing weekly by photo (every Thursday )

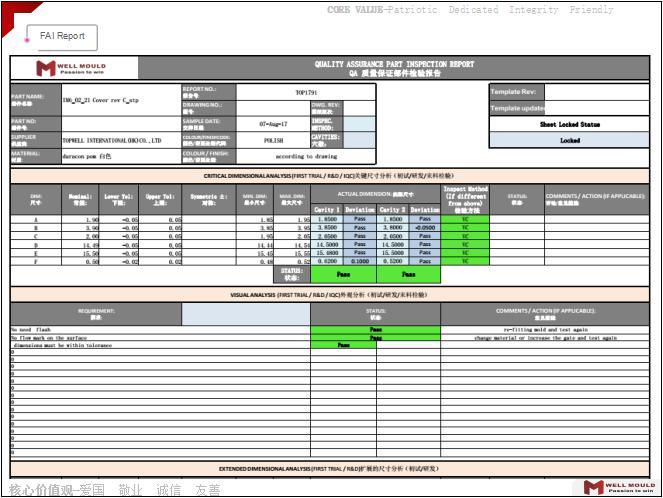

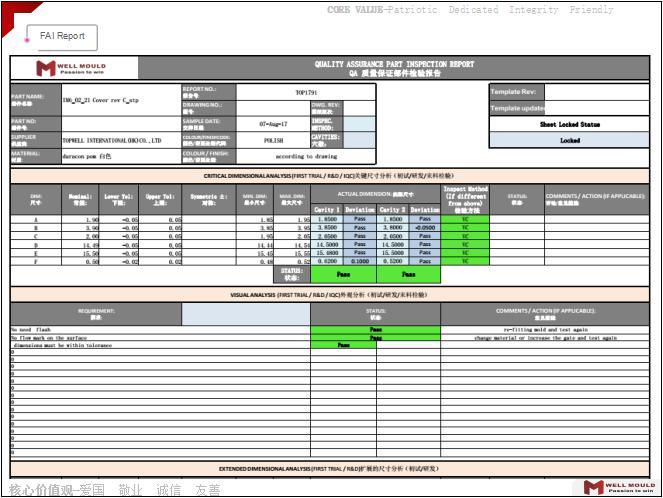

3. Mold trial report

->Record each mold trial status by photos and words description (Every trial)

->Record each mold trial status by video-3 consequent cycle times(Every trial)

4. Mold setting parameter every trial

->record the mold trial parameter on machine,

5. Part ISIR (Inspection report)

->measure the dimension according to drawing, --at least 3 or 5 parts

6. Mold trial issue report

->Record the part issue and solution by photo and words

7. V MC(virtual mold check )

->take mold photos with all mold devices (before mold dispatch )

Welcome get in touch at hardy. Hu@wellmoulding. COM or call on +86-18038083785

Our Mission:

. Listen to our customers

. Understand their product

. Provide value through innovation

. Build a relationship founded on trust, respect and mutual success