| 1 | Business type | Manufacturer |

| 2 | Standard: | GB 5237-2008;EN755,etc |

| 3 | Product series: | Aluminium profile for building material and industrial materail |

| 4 | Price: | Based on SMM Aluminium Ingot price(www.Smm.Cn) + processing Fee |

| 5 | Payment term: | T/T, L/C at sight |

| 6 | Surface treatment: | Mill finish,Anodizing, Powder coating, electrophoresis, wooden finish,heat insulting, PVDF,etc |

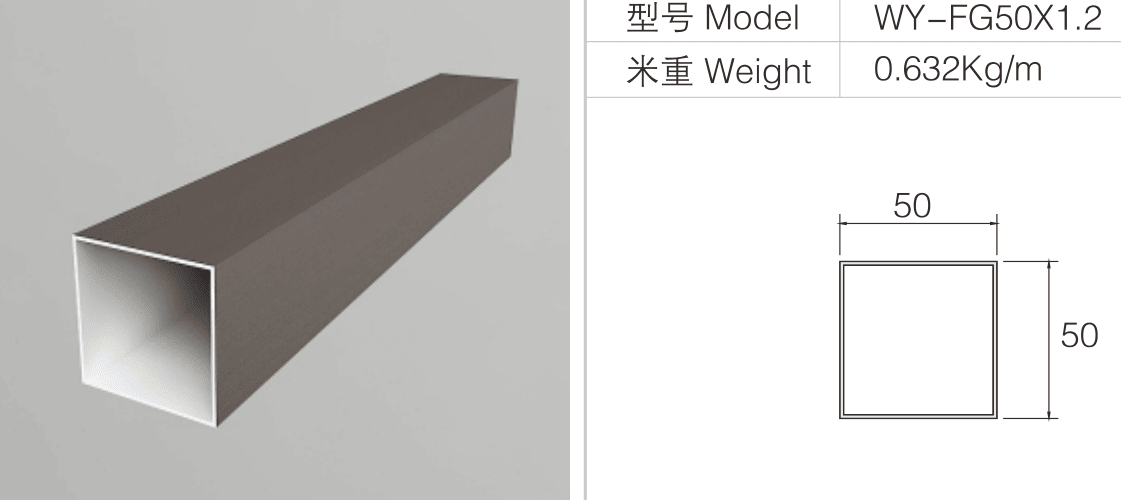

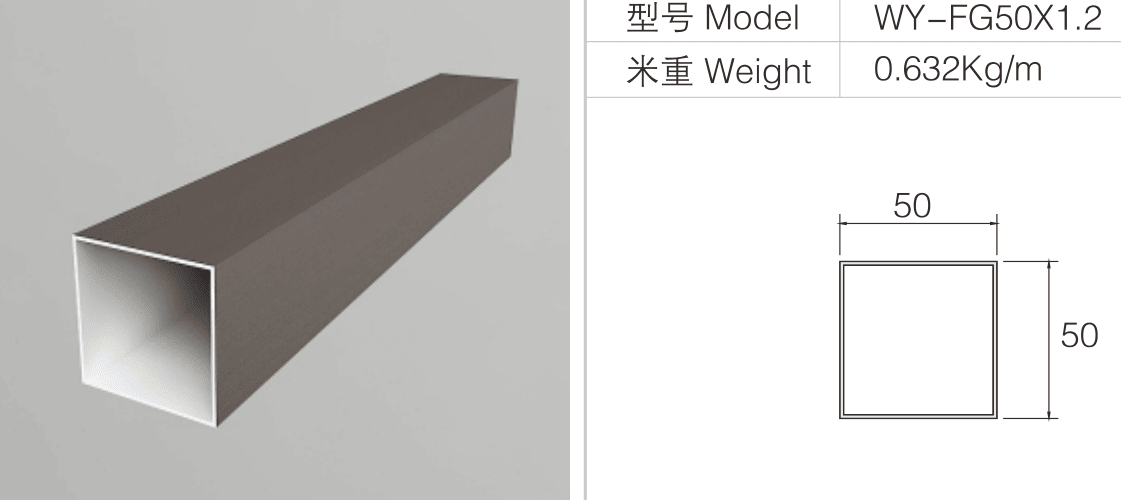

Specification:

| 7 | Alloy: | 6063, 6060, 6061, 6005, 7005 |

| 8 | State: | T4/ T5/T6 |

| 9 | Length | 1m-7m, generally 5.85m for container |

| 10 | Normal Anodizing thickness: | AVERAGE >10 micro, |

| 11 | Normal powder coating thickness: | >40micro |

| 12 | Thickness: | 0.6mm,0.8mm,1.0mm,1.2mm,1.4mm,2.0mm,3.0mm,etc |

Other information

| 13 | Price | SMM/LME Primary ingot price + the most competitive conversion cost |

| 14 | Mould policy | Genarally each item purchased volume get to 5tons , refund mould payment |

| 15 | Delivery timetable | Within 20 days from the order time |

| 16 | Payment term | 30% deposit, the balance pay against B/L copy within 7 days |

| 17 | Packing standard | Inside protection film, outsiede shrinking film or thick paper |

| 18 | CERTIFICATION | SGS /TUV - ISO9001:2008 - ISO14001:2004 |

| 19 | Usage | Sliding, casement,casementmet, windows ,doors, curtain wall,industry |

| 20 | OEM | Customized aluminium profiles are available |

The classification of aluminum alloy profiles of aluminum alloy profile is introduced:

The classification of aluminum alloy profiles of aluminum alloy profile is introduced:Below to introduce the classification of aluminium alloy profiles:

A, according to use can be divided into the following categories:

1.The doors and Windows of building doors and Windows aluminum (two) is divided into doors and Windows and curtain wall;

2.CPU radiator dedicated radiator aluminum;

3.Aluminum alloy aluminum shelves, they differ in that the different section shape, but are produced by melt extrusion;

4.Industrial aluminum profile:Mainly used in automatic machinery and equipment, sealing cover skeleton and companies according to their own custom mould machinery and equipment requirements, such as assembly line conveyor belt, lifting machine, glue machine, testing equipment, etc., and mostly in the clean room use electronic machinery industry.

Second, according to the alloy composition classification:

Can be divided into 1024, 2011, 6063, 6061, 6082, 7075, such as aluminum alloy nameplate, six of them are the most common.Ratio of different brands differ in various metal composition is different, in addition to the commonly used aluminum doors and Windows, such as 60 series, 70 series, 80 series, 90 series, curtain wall series and so on architectural aluminum, industrial aluminum profiles with no clear model distinguish, most plants are the actual drawing processing according to the customer.

Three, classified according to the requirements of surface treatment:

1.Anodized aluminum;

2.Electro-deposition aluminium;

3.Powder coating aluminum;

4.The wood grain transfer printing aluminum;

5.Wrot aluminum.

Introduction to edit

Aluminium alloy profile is the most widely used in industry of non-ferrous metal structural materials, in aviation, aerospace, automotive, machinery manufacturing, shipbuilding, construction, decoration.And have been extensively applied in chemical industry.As the science and technology in recent years, as well as the rapid development of industrial economy, the demand for aluminum alloy welding structure is increasing, also make the weldability of aluminum alloy and research.Aluminum alloy is widely used to promote the development of aluminum alloy welding technology, at the same time, the development of welding technology and expand the application field of aluminum alloy, thus the welding technology of aluminum alloy is becoming one of the hot spot of research.

Performance of the editor

The density of pure aluminum (rho = 2.7 g/cm3), is about 1/3 of the iron, low melting point (660 ºC), aluminum is face-centered cubic structure, therefore, has the very high plasticity (delta:32 ~ 40%, and bits of:70 ~ 90%), easy to machining, can be made into all kinds of shapes, plates, corrosion resistant performance is good.But the strength of pure aluminium is very low, annealing state sigma b value is about 8 KGF/was, therefore, not as a structural material.Through the long-term production practice and scientific experiment, people gradually to add alloy elements and using the method of heat treatment to strengthen aluminum, it's got a series of aluminum alloy.Add some elements to form the alloy while maintaining the advantages of pure aluminum light can also has high strength, sigma b value can reach 24 ~ 60 KGF/was respectively.So that its "strength" (the ratio of intensity and the proportion of sigma b/rho) is better than a lot of alloy steel, become the ideal structural material, widely used in machinery manufacturing, transportation, machinery and aviation industry, the aircraft fuselage, skin, such as compressor with aluminum alloy manufacture, in order to reduce weight.The welding of aluminum alloy instead of steel material, the structure can reduce more than 50% in weight.

The classification of aluminum alloy profiles of aluminum alloy profile is introduced

Below to introduce the classification of aluminium alloy profiles:

A, according to use can be divided into the following categories:

1.The doors and Windows of building doors and Windows aluminum (two) is divided into doors and Windows and curtain wall;

2.CPU radiator dedicated radiator aluminum;

3.Aluminum alloy aluminum shelves, they differ in that the different section shape, but are produced by melt extrusion;

4.Industrial aluminum profile:Mainly used in automatic machinery and equipment, sealing cover skeleton and companies according to their own custom mould machinery and equipment requirements, such as assembly line conveyor belt, lifting machine, glue machine, testing equipment, etc., and mostly in the clean room use electronic machinery industry.

Second, according to the alloy composition classification:

Can be divided into 1024, 2011, 6063, 6061, 6082, 7075, such as aluminum alloy nameplate, six of them are the most common.Ratio of different brands differ in various metal composition is different, in addition to the commonly used aluminum doors and Windows, such as 60 series, 70 series, 80 series, 90 series, curtain wall series and so on architectural aluminum, industrial aluminum profiles with no clear model distinguish, most plants are the actual drawing processing according to the customer.

Three, classified according to the requirements of surface treatment:

1.Anodized aluminum;

2.Electro-deposition aluminium;

3.Powder coating aluminum;

4.The wood grain transfer printing aluminum;

5.Wrot aluminum.

Introduction to edit

Aluminium alloy profile is the most widely used in industry of non-ferrous metal structural materials, in aviation, aerospace, automotive, machinery manufacturing, shipbuilding, construction, decoration.And have been extensively applied in chemical industry.As the science and technology in recent years, as well as the rapid development of industrial economy, the demand for aluminum alloy welding structure is increasing, also make the weldability of aluminum alloy and research.Aluminum alloy is widely used to promote the development of aluminum alloy welding technology, at the same time, the development of welding technology and expand the application field of aluminum alloy, thus the welding technology of aluminum alloy is becoming one of the hot spot of research.

Contact information:

George Suen:

Whatsup:+86 15705361126

Founded in 2001, Shandong Weiye Aluminum Co., Ltd. is located in Linqu County, Weifang City, which is known as "The First County of Aluminum Sections (in North Area of the Yangtze River) of China", which covers an area of more than 300, 000m2 and has the total assets of RMB 420 million and 1, 560 employees (including 127 senior and intermediate technicians). The company integrates processing and sale of aluminum sections, processing and installation of aluminum doors, windows and curtain walls as well as import & export trading of aluminum and aluminum products, and is a council unit of China Nonferrous Metals Industry Association, a council unit of China Nonferrous Metals Industry Processing Association, a member unit of China Architectural Metal Structure Association, a standing council unit of Shandong Construction Machinery Industry Association, a backbone enterprise of Shandong Construction Machinery Industry as well as a Top-500 Enterprise in China Building Materials Industry.

The company mainly produces anodic oxidized tinct, elecrophoretic coating, powder spraying, thermal insulation, fluorocarbon spraying, wooden transfer sections and other products falling into seven series and more than 3, 000 section models, with the annual productivity of 100, 000 tons.

Since its foundation, the company has been adhering to the business philosophy of "Honest, Trustworthy, Pioneering, Innovative", insisting on the policy of "Credible Operation, Technological Innovation, First-class Quality, First-class Service", seriously carrying out the principle of "People-oriented" and strictly implementing the management philosophy of "Strict, Refined, High, Clear", with the production scale constantly enlarged, the management level ceaselessly enhanced, the product quality continuously improved, as well as the economic benefits progressively increased in successive years. The company has successively passed the certifications of ISO9001: 2008 Quality Management System and ISO14001: 2004 Environmental Management System, and won "AAA-class Standardization Good Behavior Certificate", "National Inspection Exemption Certificate for Product Quality", "Shandong Famous Brand" and "Shandong Well-known Trademark"

Since 2006, the company has been continuously awarded "Weifang Credible Private Enterprise" and "Special-grade Credible Private Enterprise" by Weifang Review Committee of Credible Private Enterprise, "2008 Weifang Eco-friendly Enterprise" by Weifang Environmental Protection Agency, "Weifang Optimal Credit Integrity Customer of Banking Industry" by Weifang Banking Association, "Weifang Private Scientific and Technological Enterprise", "Weifang Municipal Enterprise Technology Center" and other series of honorary titles.

Advanced production equipment and advanced production processes are important guarantees for ensuring product quality. Over the years, the company has not begrudged the input, constantly increased the technical innovation strength, introduced the most advanced production equipment at home and abroad, and actively researched, developed and adopted advanced production processes, with the production capacity continuously enhanced, and the product quality constantly improved. The casting workshop has eliminated outdated equipment, and introduced 4 15-ton gas reflection smelting furnaces (energy-saving type) which have high temperature measurement and control accuracy and are equipped with waste gas dust collection systems and outer conductive hydraulic lifting hot top casting systems, with the equipment performance reaching the advanced level of the industry in China.