400kw Metal Foundry Industrial Induction Heating Equipment for Forge Process

| Price: |

US $ 1-100000/Set |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1/Set |

| Pay Type: |

T/T |

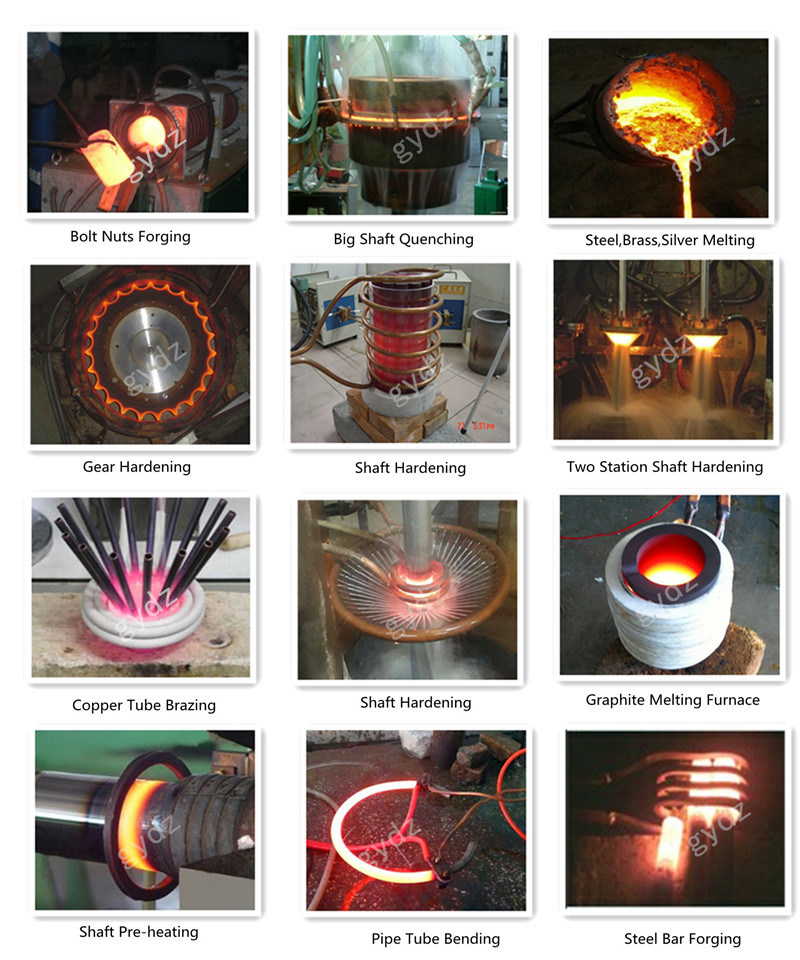

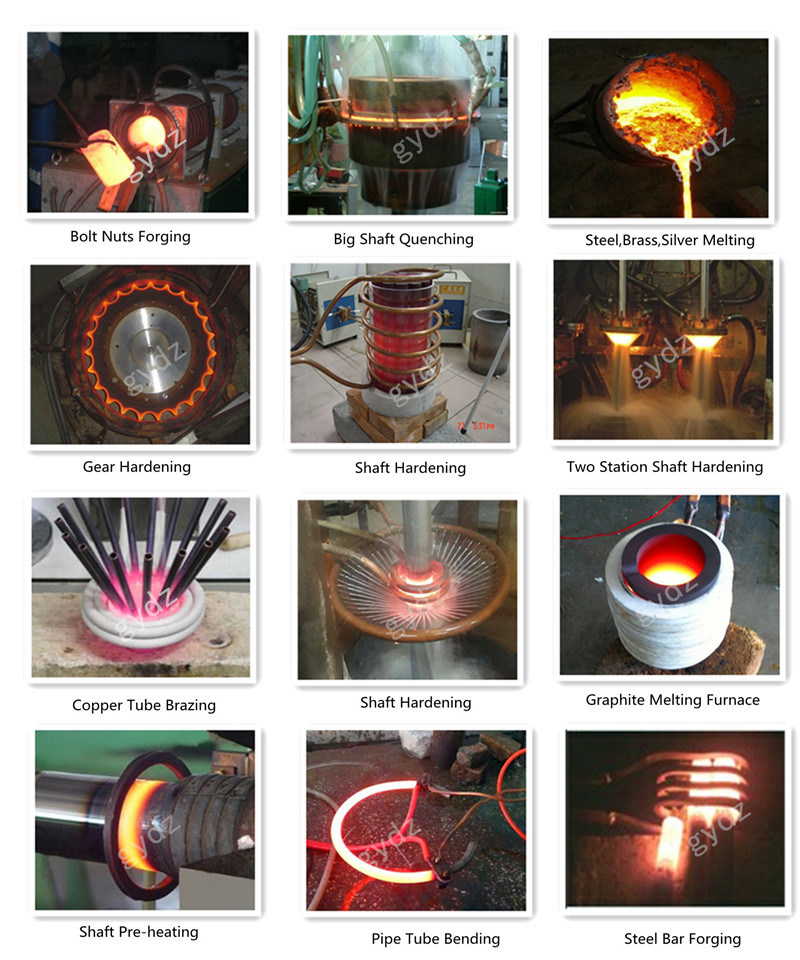

400kw Metal Foundry Industrial Induction Heating Equipment For Forge ProcessApplication of Induction Heating Equipment:

A. Heating (hot forging, hot fitting and smelting):

1 Hot forging aims to fabricate the work pieces of certain temperature (different materials require different temperatures) into other shapes through forging press with the help of punch press, forging machine or other equipments, for instances, hot extrusion of watch case, watch flan, handle, mold accessory, kitchen and table ware, art ware, standard part, fastener, fabricated mechanical part, bronze lock, rivet, steel pin and pin.

2. Hot fitting refers to the connection of different metals or metals with nonmetals through the heating based on the principle of hot expansion or hot smelting, for instances, embedded welding of copper core of computer radiator with aluminum sheet and speaker web, compound of steel and plastic tube, sealing of aluminum foil (tooth paste peel), motor rotor and sealing of tubular electric heating element.

3. Smelting mainly aims to melt the metal into liquid by using the high temperature, which is mainly applicable to the smelting of iron, steel, copper, aluminum, zinc as well as various noble metals.

B. Heat Treatment (surface quench):

It is mainly aims to change the rigidity of the metal materials through the heat treatment to work pieces. Detail applications are stated as follows:

1. Quench for various hardware and tools, such as plier, wrench, hammer, ax, screwing tools and shear (orchard shear).

2. Quench for various automobile and motorcycle fittings, such as crankshaft, connecting rod, piston pin, chain wheel, aluminum wheel, valve, rock arm shaft, semi drive shaft, small shaft and fork.

3. Various electric tools, such as gear and axes.

4. Quench for machine tools, such as lathe deck and guide rail.

5. Quench for various hardware metal parts and machined parts, such as shaft, gear (chain wheel), cam, chuck and clamp etc.

6. Quench for hardware molds, such as small-size mold, mold accessory and inner hole of mold.

C. Welding (braze welding, silver soldering and brazing)

It mainly aims to melt the solder by heating it to a certain temperature for the purpose of connecting two types of metals of the same material or different materials.

1. Welding of various hardware cutting tools, such as diamond tool, abrasive tool, drilling tool, alloy saw blade, hard alloy cutter, milling cutter, reamer, planning tool and solid center bit. 2. Welding of various hardware mechanical gadget: Silver soldering and brazing of metals of the same variety or different varieties, such as hardware toilet and kitchen products, refrigerating copper fitting, lamp decoration fitting, precision mold fitting, hardware handle, eggbeater, alloy steel and steel, steel and copper as well as copper and copper.

3. Compound pot bottom welding is mainly applicable to the braze welding of circular, square as well as other irregular plain pot bottom. It is also applicable to plain braze welding of other metals.

4. Welding of heating disc of electric hot-water kettle mainly refers to the braze welding of stainless steel flat base, aluminum sheet and tubular electric heating elements of various forms.

D. Annealing (tempering and modulation):

1. Annealing of various stainless steel products, such as stainless steel basin, annealed and extruded can, annealed folded edge, annealed sink, stainless steel tube, tableware and cup.

2. Annealing of various other metal work pieces, such as golf ball head, cue, brass lock, hardware copper fitting, kitchen knife handle, blade, aluminum pan, aluminum pail, aluminum radiator and various aluminum products.

Advantage

Nearly 20 years experience, stable and goods performance

CE,SGC,FCC,ROSH certificated

Cooperated with GM,VOLVO,HONDA and so on.

Suitable for a large range, heating, quenching, forging, melting, soldering and so on.

Less environment pollution

High efficiency,high output&high reliability

Small size &light weight

Parameter:| Model | GYS-400AB (Three phase) |

| work power | 340V-430V |

| Input current | 600A |

| fluctuating frequency | 10-50khz |

| output current | 400-10500A |

| the flow rate of cooling water | 0.08-0.16MPa 25L/Min |

| water temperature protection point | 80C |

| product size | main : 1500x1100x1150 mm |

| transformer : 1300x600x820 mm |

| net weight | main : 450kg |

| transformer : 300 kg |

Delivery Time: within 25 workdays.

Shipping Term:By sea,By air,by express.

Extra accessories accept choose,

1>Chiller

2>Customer design Coil Box

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace(Depends on Heating rod size customs design) Application Photo

| Prod Model: |

GYS-400AB |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Cooling: |

Water |

| Work Condition: |

Continuously for 24hours |

| System Control: |

IGBT |

| Application: |

Heating,Forging,Melting,Hardening and etc |

| Work Principle: |

Electromagnetic Induction Heating |

| Work Power: |

380V 3phase |

| Forging Forming Method: |

Free Forging |

| Certification: |

FCC,SGS |

Founded in 1993, Dongguan Guangyuan Inverter Electronic Equipment Factory is a private high-tech factory. Our factory is located in Wanjiang District of Dongguan City in Zhujiang Delta, with convenient transportation near No. 107 national highway and Guangshen speedway.

We have established an R&D system. It is supported by advanced engineers and professional workers, who are especially engaged in researching and developing the machinery of middle or high frequency induction heating and high frequency inverter electrolysis and galvanization power supply. Since we owned strong technique development capability, our factory has been insisting on producing new product and new craftwork to assure our leading position on technique in this field.

Under the effort of several years, our factory has produced series of high quality products in various categories. We can also exclusively produce these products on your requirement to meet you need. Our middle or high frequency induction heating equipment is produced for special voltage condition of some countries. For instance, there is single-phase 110V, three-phase 220V induction heating equipment for America and Japan and three-phase 415V, 440V induction heating equipment for such southwestern Asia countries as Malay and Thailand.

Our factory has a wholesome distribution network. Our products are delivered to America, Europe and southwestern Asia areas. We also built up a lot of offices to provide prompt and quick service to our consumers.

At the beginning of our foundation, we advocated "work with honest and credit, service for ever". This slogan has deeply footed in the culture of our factory, becoming the soul of development and management. During the process of development, it is firmly believed that a wonderful after-sale service is the base stone for a company' S existing. Therefore, our factory takes the thought of "creating values for costumers" as the core of our managing strategies.

Chinese companies are facing the competition and challenge from the whole globe. Our factory will use advanced technology to provide better after-sale service and to find a proper position in the international market. We will hold the spirit of more professional, advanced and perseverant to pursue the wide application of our products in the market. We will also pursue the co-development and advancement with our suppliers and consumers relying on professional technology and good cooperation efforts.